Note

Go to the end to download the full example code.

Steady State Thermal Analysis of cooling holes on a representative model#

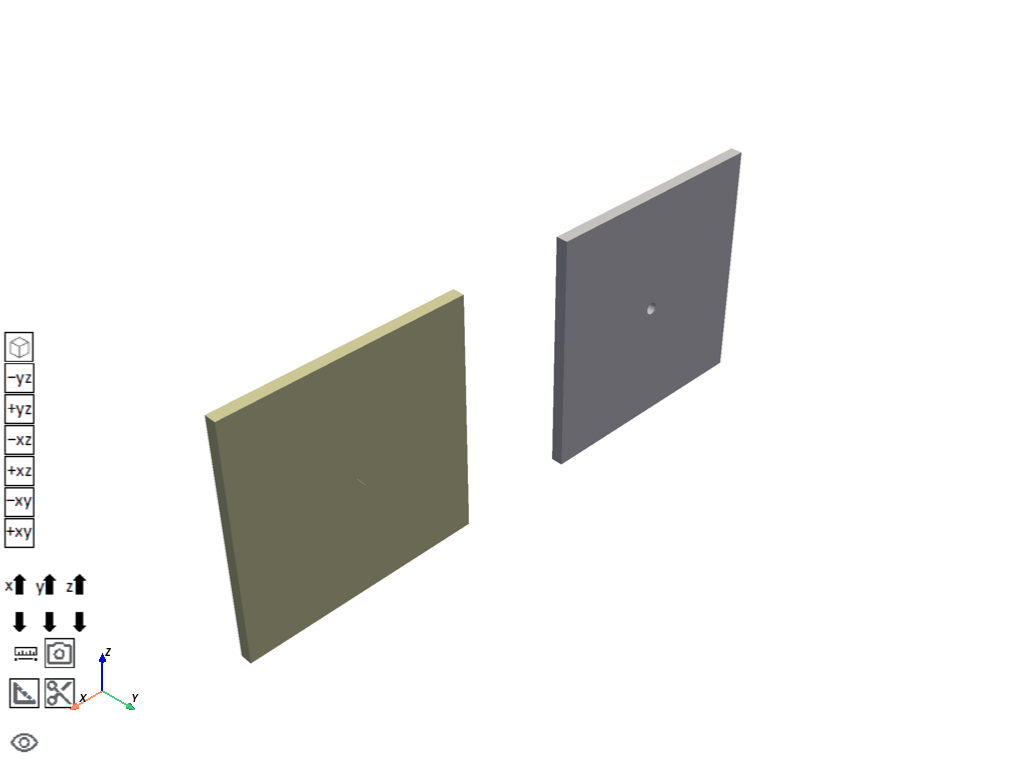

This example illustrates the process of adding a Steady State Thermal analysis to a new standalone Mechanical session, followed by executing Python scripting commands to set boundary conditions and solve a thermal simulation of a model with cooling holes. The scripts then assess the results, including temperature plots of plates and fluid lines modeled with Fluid116 elements.

Cooling holes are carefully designed small channels within turbine blades that release cool air, creating a protective layer on the blade’s surface to shield it from the intense heat of combustion gases. This film cooling technique helps maintain optimal temperatures, boost turbine efficiency, and ensure safe operation. The size, shape, and location of these holes are crucial for their effectiveness and to prevent premature failure.

The model features two plates: one equipped with cooling holes and the other without them. Fluid116 elements simulate the flow network through the holes without requiring the holes to be physically present in the geometry.

The plates are constructed from structural steel, with air flowing through the holes. The simulation involves applying convection boundary conditions to the plate surfaces, temperature boundary conditions at the line vertices, and mass flow rate boundary conditions at the fluid lines. After solving the simulation, the results are visualized with temperature plots, showing the temperature distribution on the plates and fluid lines using matplotlib.

Import the necessary libraries#

from pathlib import Path

from typing import TYPE_CHECKING

from matplotlib import image as mpimg, pyplot as plt

from ansys.mechanical.core import App

from ansys.mechanical.core.examples import delete_downloads, download_file

if TYPE_CHECKING:

import Ansys

Initialize the embedded application#

app = App(globals=globals())

print(app)

Ansys Mechanical [Ansys Mechanical Enterprise]

Product Version:252

Software build date: 06/13/2025 11:25:56

Create functions to set camera and display images#

# Set the path for the output files (images, gifs, mechdat)

output_path = Path.cwd() / "out"

def set_camera_and_display_image(

camera,

graphics,

graphics_image_export_settings,

image_output_path: Path,

image_name: str,

) -> None:

"""Set the camera to fit the model and display the image.

Parameters

----------

camera : Ansys.ACT.Common.Graphics.MechanicalCameraWrapper

The camera object to set the view.

graphics : Ansys.ACT.Common.Graphics.MechanicalGraphicsWrapper

The graphics object to export the image.

graphics_image_export_settings : Ansys.Mechanical.Graphics.GraphicsImageExportSettings

The settings for exporting the image.

image_output_path : Path

The path to save the exported image.

image_name : str

The name of the exported image file.

"""

# Set the camera to fit the mesh

camera.SetFit()

# Export the image with the specified settings

image_path = image_output_path / image_name

graphics.ExportImage(str(image_path), image_export_format, graphics_image_export_settings)

# Display the exported image

display_image(image_path)

def display_image(

image_path: str,

pyplot_figsize_coordinates: tuple = (16, 9),

plot_xticks: list = [],

plot_yticks: list = [],

plot_axis: str = "off",

) -> None:

"""Display the image with the specified parameters.

Parameters

----------

image_path : str

The path to the image file to display.

pyplot_figsize_coordinates : tuple

The size of the figure in inches (width, height).

plot_xticks : list

The x-ticks to display on the plot.

plot_yticks : list

The y-ticks to display on the plot.

plot_axis : str

The axis visibility setting ('on' or 'off').

"""

# Set the figure size based on the coordinates specified

plt.figure(figsize=pyplot_figsize_coordinates)

# Read the image from the file into an array

plt.imshow(mpimg.imread(image_path))

# Get or set the current tick locations and labels of the x-axis

plt.xticks(plot_xticks)

# Get or set the current tick locations and labels of the y-axis

plt.yticks(plot_yticks)

# Turn off the axis

plt.axis(plot_axis)

# Display the figure

plt.show()

Download the required files#

# Download the geometry file

geometry_path = download_file("cooling_holes_geometry.pmdb", "pymechanical", "embedding")

# Download the material file

mat_path = download_file("cooling_holes_material_file.xml", "pymechanical", "embedding")

Configure graphics for image export#

# Define the graphics and camera objects

graphics = app.Graphics

camera = graphics.Camera

# Set the camera orientation to the isometric view and set the camera to fit the model

camera.SetSpecificViewOrientation(ViewOrientationType.Iso)

camera.SetFit()

# Set the image export format and settings

image_export_format = GraphicsImageExportFormat.PNG

settings_720p = Ansys.Mechanical.Graphics.GraphicsImageExportSettings()

settings_720p.Resolution = (

Ansys.Mechanical.DataModel.Enums.GraphicsResolutionType.EnhancedResolution

)

settings_720p.Background = Ansys.Mechanical.DataModel.Enums.GraphicsBackgroundType.White

settings_720p.Width = 1280

settings_720p.Height = 720

settings_720p.CurrentGraphicsDisplay = False

# Define the model

model = app.Model

Define Python variables#

Store all main tree nodes as variables

geometry = model.Geometry

mesh = model.Mesh

materials = model.Materials

coordinate_systems = model.CoordinateSystems

named_selections = model.NamedSelections

Import the geometry#

# Add the geometry import to the geometry import group

geometry_import_group = model.GeometryImportGroup

geometry_import = geometry_import_group.AddGeometryImport()

# Set the geometry import format and settings

geometry_import_format = Ansys.Mechanical.DataModel.Enums.GeometryImportPreference.Format.Automatic

geometry_import_preferences = Ansys.ACT.Mechanical.Utilities.GeometryImportPreferences()

geometry_import_preferences.ProcessNamedSelections = True

geometry_import_preferences.NamedSelectionKey = ""

geometry_import_preferences.ProcessMaterialProperties = True

geometry_import_preferences.ProcessCoordinateSystems = True

# Import the geometry with the specified settings

geometry_import.Import(geometry_path, geometry_import_format, geometry_import_preferences)

Define and select BIN units system#

Define the unit system for the model as Standard BIN (BTU, inch).

app.ExtAPI.Application.ActiveUnitSystem = MechanicalUnitSystem.StandardBIN

Assign materials#

Import material from xml file and assign it to bodies

materials.Import(mat_path)

<System.Collections.Generic.List[Material] object at 0x7f18b8669740>

Assign geometrical and material properties#

Specify section properties and assign them to geometry

geometry.Activate()

fluid_line1 = geometry.Children[2].Children[0] # Activate fluid line Body

fluid_line1.ModelType = PrototypeModelType.ModelPhysicsTypeFluid

fluid_line1.Material = "Air"

fluid_line1.FluidCrossArea = Quantity(3.1414, "in in")

fluid_line2 = geometry.Children[3].Children[0] # Activate fluid line Body

fluid_line2.ModelType = PrototypeModelType.ModelPhysicsTypeFluid

fluid_line2.Material = "Air"

fluid_line2.FluidCrossArea = Quantity(3.1414, "in in")

# Visualize the model in 3D

app.plot()

[]

Define coordinate system#

Specify cylindrical coordinate system for applying boundary conditions

coordinate_systems.Activate()

coordinate_system_101 = coordinate_systems.AddCoordinateSystem()

coordinate_system_101.CoordinateSystemType = CoordinateSystemTypeEnum.Cylindrical

coordinate_system_101.OriginDefineBy = CoordinateSystemAlignmentType.Component

coordinate_system_101.OriginDefineBy = CoordinateSystemAlignmentType.Fixed

coordinate_system_101.OriginX = Quantity(2, "in")

coordinate_system_101.OriginZ = Quantity(-0.5, "in")

coordinate_system_101.PrimaryAxis = CoordinateSystemAxisType.PositiveZAxis

coordinate_system_101.PrimaryAxisDefineBy = CoordinateSystemAlignmentType.GlobalY

coordinate_system_101.SecondaryAxisDefineBy = CoordinateSystemAlignmentType.GlobalZ

Define named selections#

Create named selections used in the model

HoleFluidNodes_NS = [x for x in Tree.AllObjects if x.Name == "HoleFluidNodes"][0]

Both_Plates_NS = [x for x in Tree.AllObjects if x.Name == "Both_Plates"][0]

Fluid_Line1_NS = [x for x in Tree.AllObjects if x.Name == "Fluid_Line1"][0]

Fluid_Line2_NS = [x for x in Tree.AllObjects if x.Name == "Fluid_Line2"][0]

Line1_vertex_NS = [x for x in Tree.AllObjects if x.Name == "Line1_vertex"][0]

Line2_vertex_NS = [x for x in Tree.AllObjects if x.Name == "Line2_vertex"][0]

Bottom_Surface_Plates_NS = [x for x in Tree.AllObjects if x.Name == "Bottom_Surface_Plates"][0]

Top_Surface_Plates_NS = [x for x in Tree.AllObjects if x.Name == "Top_Surface_Plates"][0]

Hole_Cyl_Surface_NS = [x for x in Tree.AllObjects if x.Name == "Hole_Cyl_Surface"][0]

Fluidlines_NS = [x for x in Tree.AllObjects if x.Name == "Fluidlines"][0]

# Create named selection for elements at the hole

named_selections = model.NamedSelections

named_selection = named_selections.AddNamedSelection()

named_selection.ScopingMethod = GeometryDefineByType.Worksheet

named_selection.GenerationCriteria.Add(None)

named_selection.GenerationCriteria[0].EntityType = SelectionType.MeshElement

named_selection.GenerationCriteria[0].Criterion = SelectionCriterionType.LocationX

named_selection.GenerationCriteria[0].Operator = SelectionOperatorType.LessThanOrEqual

named_selection.GenerationCriteria[0].Value = Quantity("2.5e-2 [in]")

cyl_cs = DataModel.GetObjectsByName("Coordinate System")

named_selection.GenerationCriteria[0].CoordinateSystem = cyl_cs[0]

named_selection.GenerationCriteria.Add(None)

named_selection.GenerationCriteria[1].Action = SelectionActionType.Convert

named_selection.GenerationCriteria[1].EntityType = SelectionType.MeshNode

active_sel = named_selection.GenerationCriteria[1]

active_sel.Active = False

named_selection.Generate()

named_selection.Name = r"""HoleElements"""

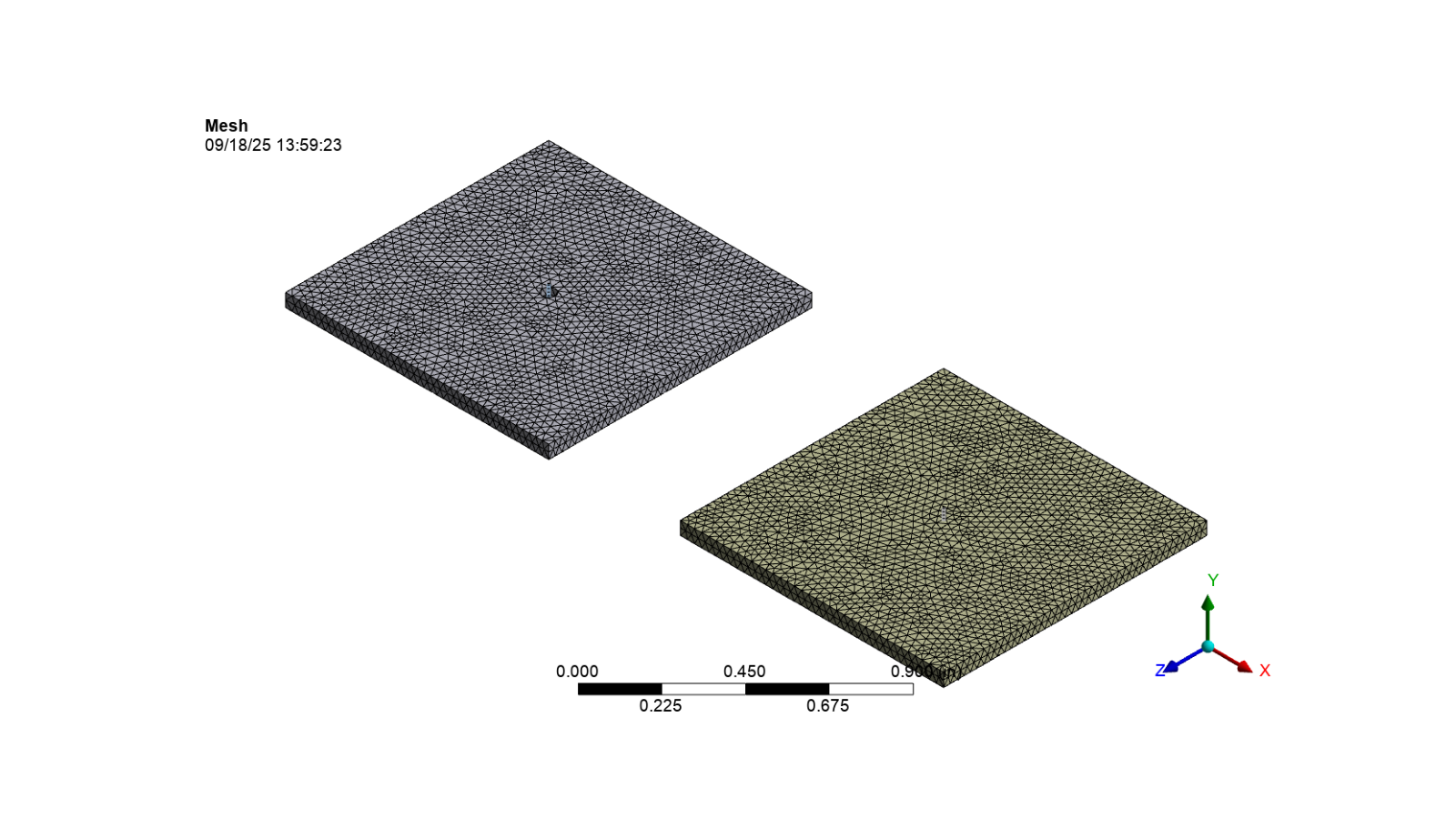

Define mesh controls and generate the mesh#

Mesh the model

mesh.Activate()

mesh.ElementSize = Quantity(0.5, "in")

mesh.UseAdaptiveSizing = False

mesh.CaptureCurvature = True

mesh.CaptureProximity = True

mesh.GrowthRateSF = 1.85

mesh.DefeatureTolerance = Quantity(0.000375, "in")

automatic_method = mesh.AddAutomaticMethod()

automatic_method.ScopingMethod = GeometryDefineByType.Component

automatic_method.NamedSelection = Both_Plates_NS

automatic_method.Method = MethodType.AllTriAllTet

sizing = mesh.AddSizing()

sizing.ScopingMethod = GeometryDefineByType.Component

sizing.NamedSelection = Fluidlines_NS

sizing.ElementSize = Quantity(1e-2, "in")

sizing.CaptureCurvature = False

sizing.CaptureProximity = False

mesh.GenerateMesh()

Display the mesh

# Activate the mesh for visualization

app.Tree.Activate([mesh])

# Set the camera to fit the model and export the image

set_camera_and_display_image(camera, graphics, settings_720p, output_path, "mesh.png")

Define analysis#

Add a Steady State Thermal Analysis

steady_state_thermal = model.AddSteadyStateThermalAnalysis()

steady_state_thermal_analysis = model.Analyses[0].AnalysisSettings

# Define the static structural analysis solution

solution = model.Analyses[0].Solution

Apply loads and boundary conditions#

Add convection loads, body temperatures, and mass flow rates

steady_state_thermal.Activate()

# Apply convection at the surfaces

convection_1 = steady_state_thermal.AddConvection()

convection_1.Location = Top_Surface_Plates_NS

convection_1.FilmCoefficient = Quantity(2.9e-4, "BTU sec^-1 in^-1 in^-1 F^-1")

convection_1.AmbientTemperature = Quantity(1700, "F")

convection_2 = steady_state_thermal.AddConvection()

convection_2.Location = Bottom_Surface_Plates_NS

convection_2.FilmCoefficient = Quantity(5e-4, "BTU sec^-1 in^-1 in^-1 F^-1")

convection_2.AmbientTemperature = Quantity(900, "F")

convection_3 = steady_state_thermal.AddConvection()

convection_3.Location = Hole_Cyl_Surface_NS

convection_3.FilmCoefficient = Quantity(9.65e-4, "BTU sec^-1 in^-1 in^-1 F^-1")

convection_3.AmbientTemperature = Quantity(900, "F")

convection_3.HasFluidFlow = True

convection_3.DisplayConnectionLines = True

convection_3.FluidFlowSelection = Fluid_Line1_NS

# Apply temperature at the line vertices

temperature_1 = steady_state_thermal.AddTemperature()

temperature_1.Location = Line1_vertex_NS

temperature_1.Magnitude = Quantity(900, "F")

temperature_2 = steady_state_thermal.AddTemperature()

temperature_2.Location = Line2_vertex_NS

temperature_2.Magnitude = Quantity(900, "F")

# Apply mass flow rate at the fluid lines

mass_flow_rate_1 = steady_state_thermal.AddMassFlowRate()

mass_flow_rate_1.Location = Fluid_Line1_NS

mass_flow_rate_1.Magnitude.Output.SetDiscreteValue(0, Quantity(9.9999e-4, "lbm sec^-1"))

mass_flow_rate_2 = steady_state_thermal.AddMassFlowRate()

mass_flow_rate_2.Location = Fluid_Line2_NS

mass_flow_rate_2.Magnitude.Output.SetDiscreteValue(0, Quantity(9.9999e-4, "lbm sec^-1"))

Insert command snippet to create surface effect elements at the hole#

command_snippet = steady_state_thermal.AddCommandSnippet()

command_snippet.Input = r"""

FINISH

/prep7

cmsel,s,HoleElements !Select elements that represent where the hole is

nsle,s !Select the nodes for these elements

cm,holenodes,node !Store the nodes for these elements as a component

esel,inve !Switch selection to inverse of these elements

esel,r,ename,,291 !Reselect just the solid elements

nsle,s !Select the nodes for these elements

cmsel,r,holenodes !reselect nodes from the holenodes component

!results in nodes at the interfaces being selected

/com, now nodes at the interface are selected and elements

/com, (minus the elements where the hole would be) are selected

/com, Create a new surface effect element type

*get,maxetyp,ETYP,0,NUM,MAX

newsurftyp=maxetyp+1

ET,newsurftyp,SURF152

mat,newsurftyp

type,newsurftyp

real,newsurftyp

esurf,all

KEYOPT,newsurftyp,5,1

KEYOPT,newsurftyp,8,2

/com, Now need to attach these new surface effect elements to the fluid 116 elements

/com, that pass through where the hole will be store the element centroids of the new

/com, surface effect elements using mask arrays. First get a list of the new surface

/com, effect elements and the mask array

esel,s,type,,newsurftyp

*del,elemnums,,nopr

*vget,elemnums,elem,,elist

*del,elemmask,,nopr

*vget,elemmask,elem,,esel

/com, Get count of new surface effect elements and maxelement number for loops

*get,surfelemcount,elem,,count

*get,maxelem,elem,,num,maxd

/com, store array of all centroids in model

*del,elemcent,,nopr

*dim,elemcent,array,maxelem,3

*vget,elemcent(1,1),elem,,cent,x

*vget,elemcent(1,2),elem,,cent,y

*vget,elemcent(1,3),elem,,cent,z

/com, Compress down to centroids of new surface effect elements

*del,surfelemcent,,nopr

*dim,surfelemcent,array,surfelemcount,3

*vmask,elemmask

*vfun,surfelemcent(1,1),comp,elemcent(1,1)

*vmask,elemmask

*vfun,surfelemcent(1,2),comp,elemcent(1,2)

*vmask,elemmask

*vfun,surfelemcent(1,3),comp,elemcent(1,3)

*del,elemcent,,nopr

*del,elemmask,,nopr

cmsel,s,holefluidnodes

/com, Loop through each surface effect element and find the closest fluid node

/com, then assign it as the extra node for that surface effect element

totalarea=0

*do,eliter,1,surfelemcount,1

closestnode=node(surfelemcent(eliter,1),surfelemcent(eliter,2),surfelemcent(eliter,3))

!For SURF152 elements with midside nodes (KEYOPT4=0)

emodif,elemnums(eliter),-9,closestnode

*get,elemarea,elem,elemnums(eliter),area

totalarea=totalarea+elemarea

*enddo

/com, Add convection boundary conditions to new surface effect elements.

/com, Use expected hole surface area ratioed to actual surface effect element area

/com, to dial in proper heat transfer

/solu

alls

esel,s,type,,newsurftyp

ApplyHTC = 9.65e-4*778.2*12 !Convert to proper units, in BIN so convert BTU to in-lbf

/com, Calculate expected hole area (here it is calculated as a straight hole with known

/com, diameter and length). Could also just hardcode in surface area of the hole

HoleDia = 0.05

HoleLength = 0.05

HoleArea = 3.141592654*HoleDia*HoleLength

/com, Adjust HTC by ratio of desired area vs actual surface effect area

AdjustHTC = ApplyHTC*HoleArea/totalarea

sf,all,conv,AdjustHTC,900

alls """

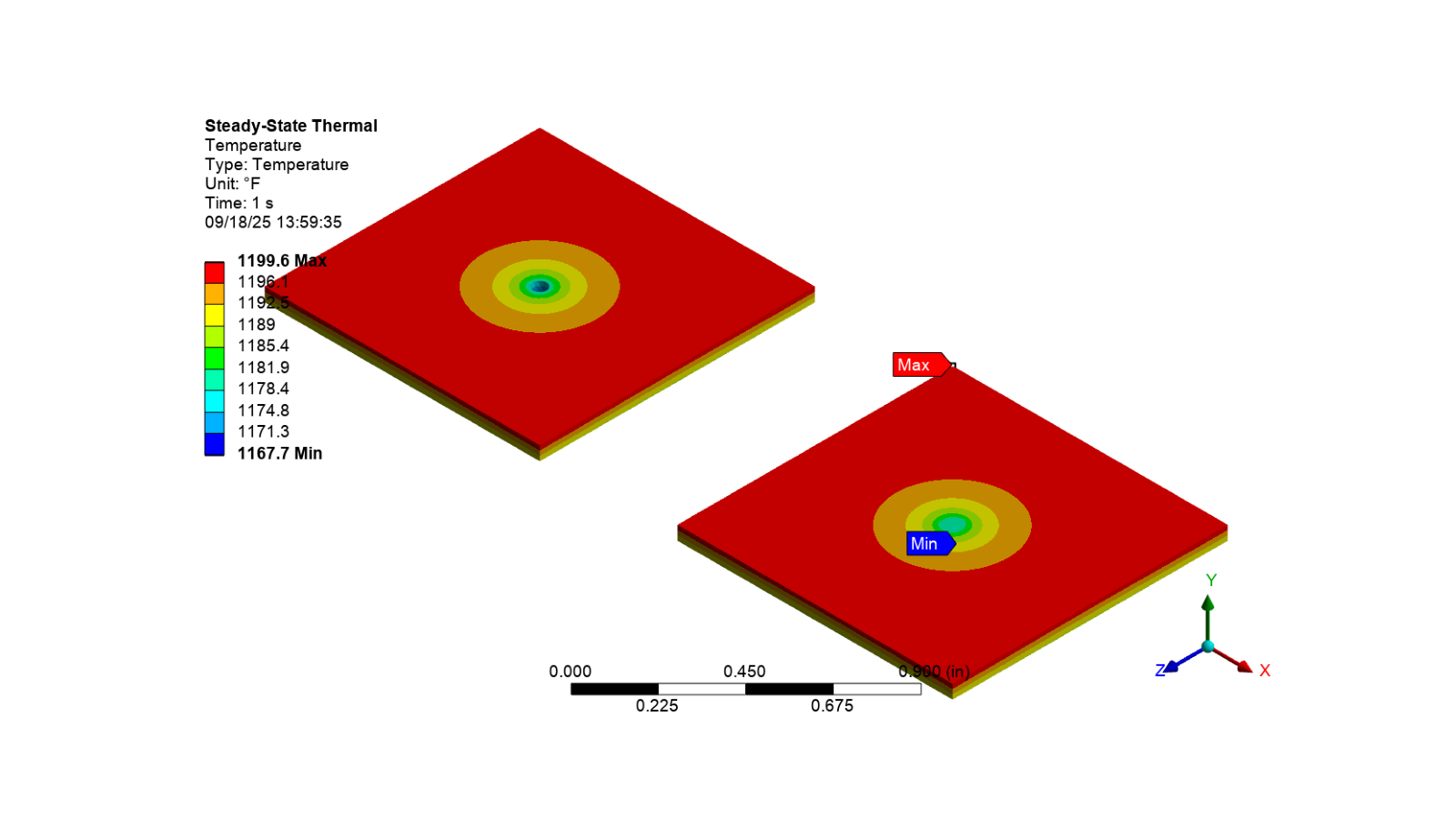

Insert results#

Insert temperature results

temp_plot_both_plates = solution.AddTemperature()

temp_plot_both_plates.Location = Both_Plates_NS

temp_plot_fluidlines = solution.AddTemperature()

temp_plot_fluidlines.Location = Fluidlines_NS

Solve#

solution.Solve(True)

STAT_SS = solution.Status

Postprocessing#

camera.SetFit()

camera.SceneHeight = Quantity(2.0, "in")

Display the temperature plots for both plates

# Activate the temperature results for both plates

app.Tree.Activate([temp_plot_both_plates])

# Set the extra model display to no wireframe

graphics.ViewOptions.ResultPreference.ExtraModelDisplay = (

Ansys.Mechanical.DataModel.MechanicalEnums.Graphics.ExtraModelDisplay.NoWireframe

)

# Set the camera to fit the model and export the image

image_path = output_path / "temp_plot_both_plates.png"

graphics.ExportImage(str(image_path), image_export_format, settings_720p)

# Display the exported image

display_image(image_path)

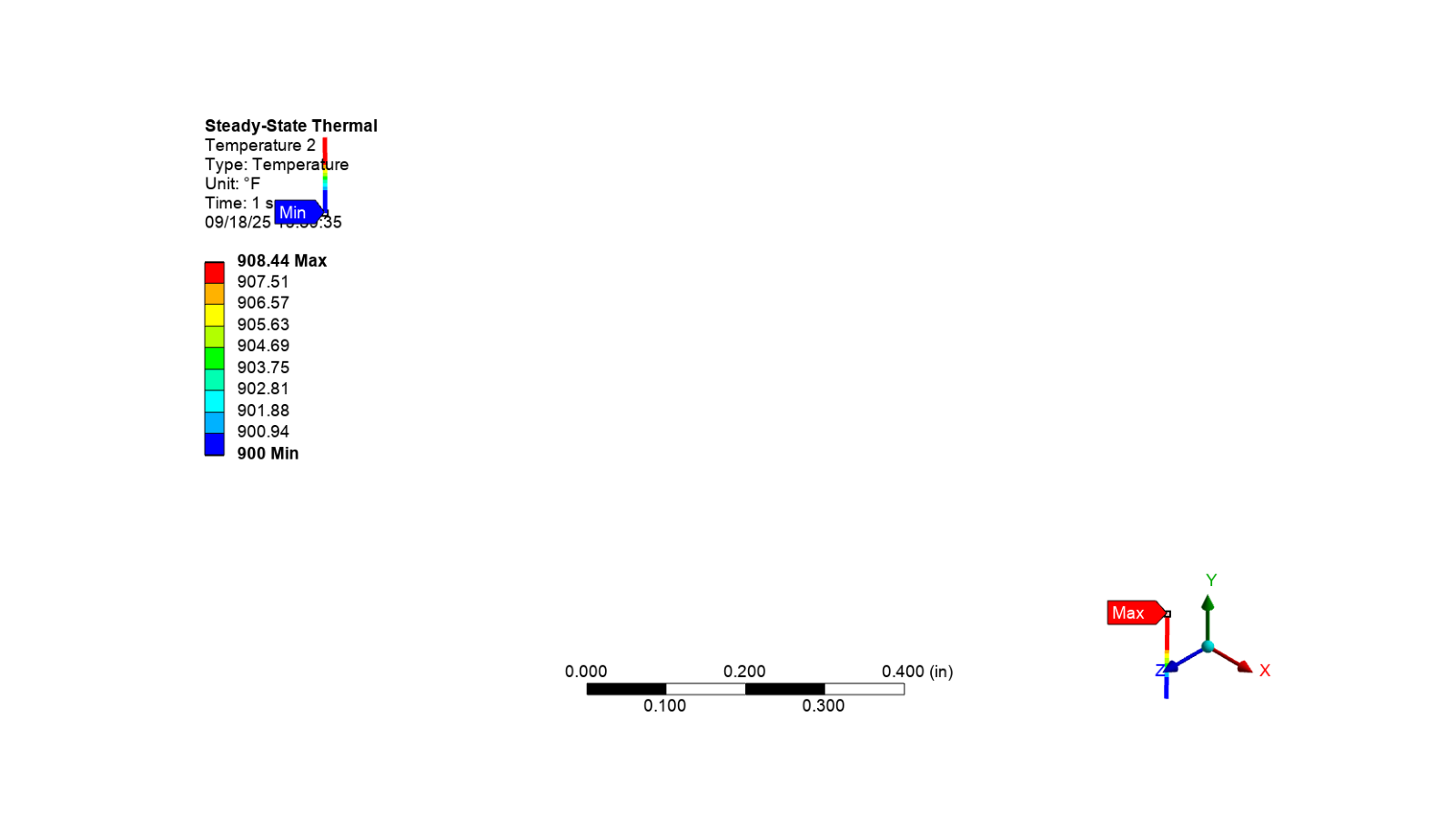

Display the temperature plots for fluid lines

# Activate the temperature results for fluid lines

app.Tree.Activate([temp_plot_fluidlines])

# Set the camera to fit the model and export the image

# Set the camera to fit the model and export the image

image_path = output_path / "temp_plot_fluidlines.png"

graphics.ExportImage(str(image_path), image_export_format, settings_720p)

# Display the exported image

display_image(image_path)

Clean up the project#

# Save the project

mechdat_file = output_path / "cooling_holes_model.mechdat"

app.save_as(str(mechdat_file), overwrite=True)

# Close the app

app.close()

# Delete the example file

delete_downloads()

True

Total running time of the script: (0 minutes 29.402 seconds)