Note

Go to the end to download the full example code.

Steady state thermal analysis#

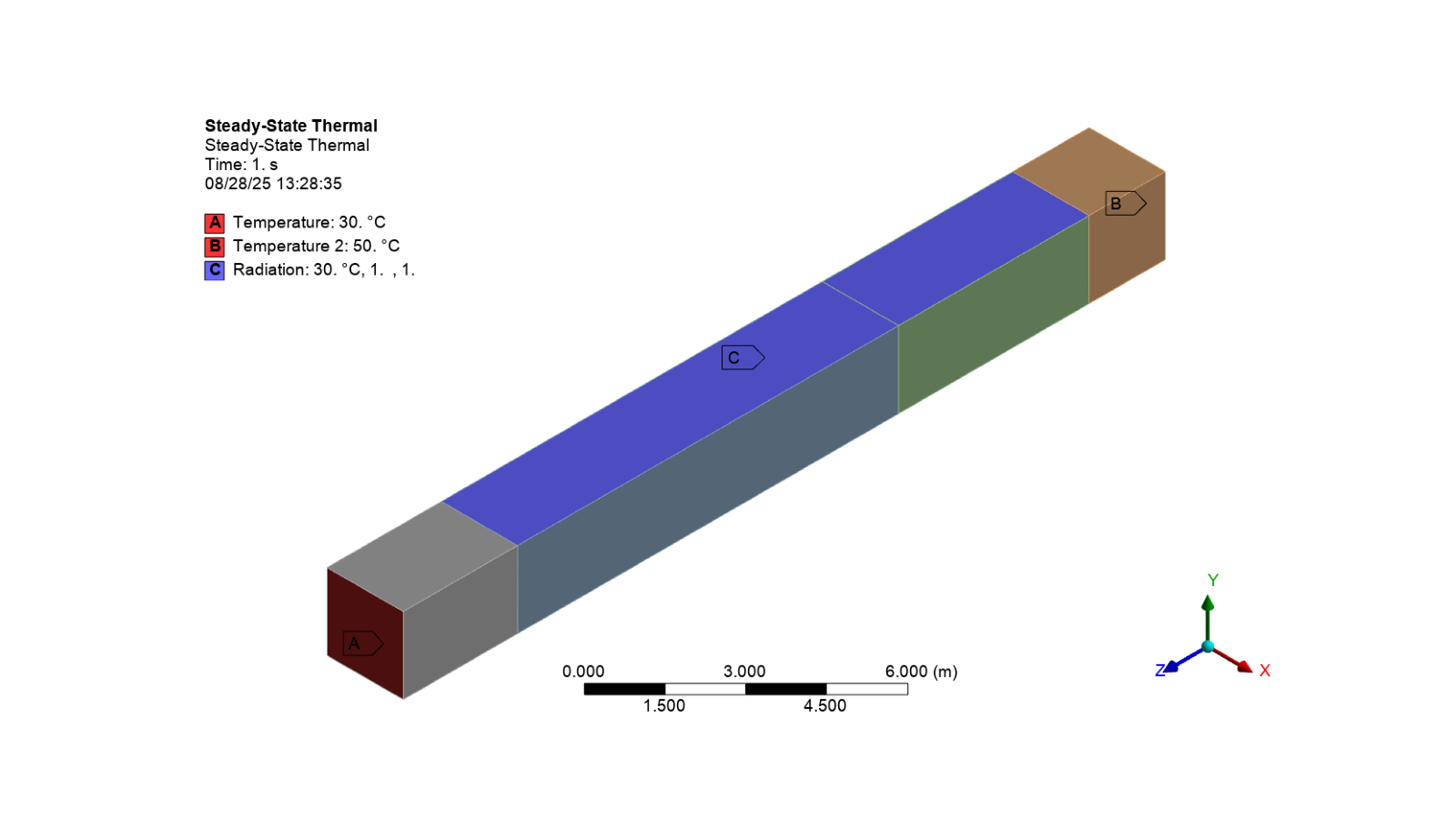

This example problem demonstrates the use of a simple steady-state thermal analysis to determine the temperatures, thermal gradients, heat flow rates, and heat fluxes that are caused by thermal loads that do not vary over time. A steady-state thermal analysis calculates the effects of steady thermal loads on a system or component, in this example, a long bar model.

Import the necessary libraries#

from pathlib import Path

from typing import TYPE_CHECKING

from matplotlib import image as mpimg, pyplot as plt

from matplotlib.animation import FuncAnimation

from PIL import Image

from ansys.mechanical.core import App

from ansys.mechanical.core.examples import delete_downloads, download_file

if TYPE_CHECKING:

import Ansys

Initialize the embedded application#

app = App(globals=globals())

print(app)

Ansys Mechanical [Ansys Mechanical Enterprise]

Product Version:261

Software build date: 01/12/2026 14:14:35

Create functions to set camera and display images#

# Set the path for the output files (images, gifs, mechdat)

output_path = Path.cwd() / "out"

def set_camera_and_display_image(

camera,

graphics,

graphics_image_export_settings,

image_output_path: Path,

image_name: str,

) -> None:

"""Set the camera to fit the model and display the image.

Parameters

----------

camera : Ansys.ACT.Common.Graphics.MechanicalCameraWrapper

The camera object to set the view.

graphics : Ansys.ACT.Common.Graphics.MechanicalGraphicsWrapper

The graphics object to export the image.

graphics_image_export_settings : Ansys.Mechanical.Graphics.GraphicsImageExportSettings

The settings for exporting the image.

image_output_path : Path

The path to save the exported image.

image_name : str

The name of the exported image file.

"""

# Set the camera to fit the mesh

camera.SetFit()

# Export the mesh image with the specified settings

image_path = image_output_path / image_name

graphics.ExportImage(str(image_path), image_export_format, graphics_image_export_settings)

# Display the exported mesh image

display_image(image_path)

def display_image(

image_path: str,

pyplot_figsize_coordinates: tuple = (16, 9),

plot_xticks: list = [],

plot_yticks: list = [],

plot_axis: str = "off",

) -> None:

"""Display the image with the specified parameters.

Parameters

----------

image_path : str

The path to the image file to display.

pyplot_figsize_coordinates : tuple

The size of the figure in inches (width, height).

plot_xticks : list

The x-ticks to display on the plot.

plot_yticks : list

The y-ticks to display on the plot.

plot_axis : str

The axis visibility setting ('on' or 'off').

"""

# Set the figure size based on the coordinates specified

plt.figure(figsize=pyplot_figsize_coordinates)

# Read the image from the file into an array

plt.imshow(mpimg.imread(image_path))

# Get or set the current tick locations and labels of the x-axis

plt.xticks(plot_xticks)

# Get or set the current tick locations and labels of the y-axis

plt.yticks(plot_yticks)

# Turn off the axis

plt.axis(plot_axis)

# Display the figure

plt.show()

Configure graphics for image export#

graphics = app.Graphics

camera = graphics.Camera

# Set the camera orientation to isometric view

camera.SetSpecificViewOrientation(ViewOrientationType.Iso)

camera.SetFit()

# Set the image export format and settings

image_export_format = GraphicsImageExportFormat.PNG

settings_720p = Ansys.Mechanical.Graphics.GraphicsImageExportSettings()

settings_720p.Resolution = GraphicsResolutionType.EnhancedResolution

settings_720p.Background = GraphicsBackgroundType.White

settings_720p.Width = 1280

settings_720p.Height = 720

settings_720p.CurrentGraphicsDisplay = False

Download the geometry file#

# Download the geometry file from the ansys/example-data repository

geometry_path = download_file("LONGBAR.x_t", "pymechanical", "embedding")

Import the geometry#

# Define the model

model = app.Model

# Add the geometry import group and set its preferences

geometry_import_group = model.GeometryImportGroup

geometry_import = geometry_import_group.AddGeometryImport()

geometry_import_format = Ansys.Mechanical.DataModel.Enums.GeometryImportPreference.Format.Automatic

geometry_import_preferences = Ansys.ACT.Mechanical.Utilities.GeometryImportPreferences()

geometry_import_preferences.ProcessNamedSelections = True

# Import the geometry file with the specified format and preferences

geometry_import.Import(geometry_path, geometry_import_format, geometry_import_preferences)

# Visualize the model in 3D

app.plot()

[]

Add steady state thermal analysis#

# Add a steady state thermal analysis to the model

model.AddSteadyStateThermalAnalysis()

# Set the Mechanical unit system to Standard MKS

app.ExtAPI.Application.ActiveUnitSystem = MechanicalUnitSystem.StandardMKS

# Get the steady state thermal analysis

stat_therm = model.Analyses[0]

# Add a coordinate system to the model

coordinate_systems = model.CoordinateSystems

# Add two coordinate systems

lcs1 = coordinate_systems.AddCoordinateSystem()

lcs1.OriginX = Quantity("0 [m]")

lcs2 = coordinate_systems.AddCoordinateSystem()

lcs2.OriginX = Quantity("0 [m]")

lcs2.PrimaryAxisDefineBy = CoordinateSystemAlignmentType.GlobalY

Create named selections and construction geometry#

Create a function to add a named selection

def setup_named_selection(name, scoping_method=GeometryDefineByType.Worksheet):

"""Create a named selection with the specified scoping method and name.

Parameters

----------

name : str

The name of the named selection.

scoping_method : GeometryDefineByType

The scoping method for the named selection.

Returns

-------

Ansys.ACT.Automation.Mechanical.NamedSelection

The created named selection.

"""

ns = model.AddNamedSelection()

ns.ScopingMethod = scoping_method

ns.Name = name

return ns

Create a function to add generation criteria to the named selection

def add_generation_criteria(

named_selection,

value,

set_active_action_criteria=True,

active=True,

action=SelectionActionType.Add,

entity_type=SelectionType.GeoFace,

criterion=SelectionCriterionType.Size,

operator=SelectionOperatorType.Equal,

):

"""Add generation criteria to the named selection.

Parameters

----------

named_selection : Ansys.ACT.Automation.Mechanical.NamedSelection

The named selection to which the criteria will be added.

value : Quantity

The value for the criteria.

active : bool

Whether the criteria is active.

action : SelectionActionType

The action type for the criteria.

entity_type : SelectionType

The entity type for the criteria.

criterion : SelectionCriterionType

The criterion type for the criteria.

operator : SelectionOperatorType

The operator for the criteria.

"""

generation_criteria = named_selection.GenerationCriteria

criteria = Ansys.ACT.Automation.Mechanical.NamedSelectionCriterion()

set_criteria_properties(

criteria,

value,

set_active_action_criteria,

active,

action,

entity_type,

criterion,

operator,

)

if set_active_action_criteria:

generation_criteria.Add(criteria)

Create a function to set the properties of the generation criteria

def set_criteria_properties(

criteria,

value,

set_active_action_criteria=True,

active=True,

action=SelectionActionType.Add,

entity_type=SelectionType.GeoFace,

criterion=SelectionCriterionType.Size,

operator=SelectionOperatorType.Equal,

):

"""Set the properties of the generation criteria.

Parameters

----------

criteria : Ansys.ACT.Automation.Mechanical.NamedSelectionCriterion

The generation criteria to set properties for.

active : bool

Whether the criteria is active.

action : SelectionActionType

The action type for the criteria.

entity_type : SelectionType

The entity type for the criteria.

criterion : SelectionCriterionType

The criterion type for the criteria.

operator : SelectionOperatorType

The operator for the criteria.

"""

if set_active_action_criteria:

criteria.Active = active

criteria.Action = action

criteria.EntityType = entity_type

criteria.Criterion = criterion

criteria.Operator = operator

criteria.Value = value

return criteria

Add named selections to the model

face1 = setup_named_selection("Face1")

add_generation_criteria(face1, Quantity("20 [m]"), criterion=SelectionCriterionType.LocationZ)

face1.Activate()

face1.Generate()

face2 = setup_named_selection("Face2")

add_generation_criteria(face2, Quantity("0 [m]"), criterion=SelectionCriterionType.LocationZ)

face2.Activate()

face2.Generate()

face3 = setup_named_selection("Face3")

add_generation_criteria(face3, Quantity("1 [m]"), criterion=SelectionCriterionType.LocationX)

add_generation_criteria(

face3,

Quantity("2 [m]"),

criterion=SelectionCriterionType.LocationY,

action=SelectionActionType.Filter,

)

add_generation_criteria(

face3,

Quantity("12 [m]"),

criterion=SelectionCriterionType.LocationZ,

action=SelectionActionType.Filter,

)

add_generation_criteria(face3, Quantity("4.5 [m]"), criterion=SelectionCriterionType.LocationZ)

add_generation_criteria(

face3,

Quantity("2 [m]"),

criterion=SelectionCriterionType.LocationY,

action=SelectionActionType.Filter,

)

face3.Activate()

face3.Generate()

body1 = setup_named_selection("Body1")

body1.GenerationCriteria.Add(None)

set_criteria_properties(

body1.GenerationCriteria[0],

Quantity("1 [m]"),

set_active_action_criteria=False,

criterion=SelectionCriterionType.LocationZ,

)

body1.GenerationCriteria.Add(None)

set_criteria_properties(

body1.GenerationCriteria[1],

Quantity("1 [m]"),

set_active_action_criteria=False,

criterion=SelectionCriterionType.LocationZ,

)

body1.Generate()

Create construction geometry

# Add construction geometry to the model

construction_geometry = model.AddConstructionGeometry()

# Add a path to the construction geometry

construction_geom_path = construction_geometry.AddPath()

# Set the coordinate system for the construction geometry path

construction_geom_path.StartYCoordinate = Quantity(2, "m")

construction_geom_path.StartZCoordinate = Quantity(20, "m")

construction_geom_path.StartZCoordinate = Quantity(20, "m")

construction_geom_path.EndXCoordinate = Quantity(2, "m")

# Add a surface to the construction geometry

surface = construction_geometry.AddSurface()

# Set the coordinate system for the surface

surface.CoordinateSystem = lcs2

# Update the solids in the construction geometry

construction_geometry.UpdateAllSolids()

Define the boundary condition and add results#

Create a function to set the location and output for the temperature boundary condition

def set_loc_and_output(temp, location, values):

"""Add a temperature set output to the boundary condition.

Parameters

----------

temp : Ansys.Mechanical.DataModel.SteadyStateThermal.Temperature

The temperature boundary condition.

location : Ansys.Mechanical.DataModel.Geometry.GeometryObject

The location of the temperature boundary condition.

values : list[Quantity]

The list of values for the temperature.

"""

temp.Location = location

temp.Magnitude.Output.DiscreteValues = [Quantity(value) for value in values]

Create a function to set the inputs and outputs for the temperature boundary condition

def set_inputs_and_outputs(

condition,

input_quantities: list = ["0 [sec]", "1 [sec]", "2 [sec]"],

output_quantities: list = ["22[C]", "30[C]", "40[C]"],

):

"""Set the temperature inputs for the boundary condition.

Parameters

----------

condition : Ansys.Mechanical.DataModel.SteadyStateThermal.Temperature

The temperature boundary condition.

inputs : list[Quantity]

The list of input values for the temperature.

"""

# Set the magnitude for temperature or the ambient temperature for radiation

if "Temperature" in str(type(condition)):

prop = condition.Magnitude

elif "Radiation" in str(type(condition)):

prop = condition.AmbientTemperature

# Set the inputs and outputs for the temperature or radiation

prop.Inputs[0].DiscreteValues = [Quantity(value) for value in input_quantities]

prop.Output.DiscreteValues = [Quantity(value) for value in output_quantities]

Add temperature boundary conditions to the steady state thermal analysis

temp = stat_therm.AddTemperature()

set_loc_and_output(temp, face1, ["22[C]", "30[C]"])

temp2 = stat_therm.AddTemperature()

set_loc_and_output(temp2, face2, ["22[C]", "60[C]"])

set_inputs_and_outputs(temp)

set_inputs_and_outputs(temp2, output_quantities=["22[C]", "50[C]", "80[C]"])

Add radiation

# Add a radiation boundary condition to the steady state thermal analysis

radiation = stat_therm.AddRadiation()

radiation.Location = face3

set_inputs_and_outputs(radiation)

radiation.Correlation = RadiationType.SurfaceToSurface

Set up the analysis settings

analysis_settings = stat_therm.AnalysisSettings

analysis_settings.NumberOfSteps = 2

analysis_settings.CalculateVolumeEnergy = True

# Activate the static thermal analysis and display the image

stat_therm.Activate()

set_camera_and_display_image(camera, graphics, settings_720p, output_path, "bc_steady_state.png")

/__w/pymechanical/pymechanical/examples/01_basic/steady_state_thermal_analysis.py:479: UserWarning: Obsolete: 'AnalysisSettings': Property is obsolete, use IAnalysisSettings instead.

analysis_settings = stat_therm.AnalysisSettings

Add results#

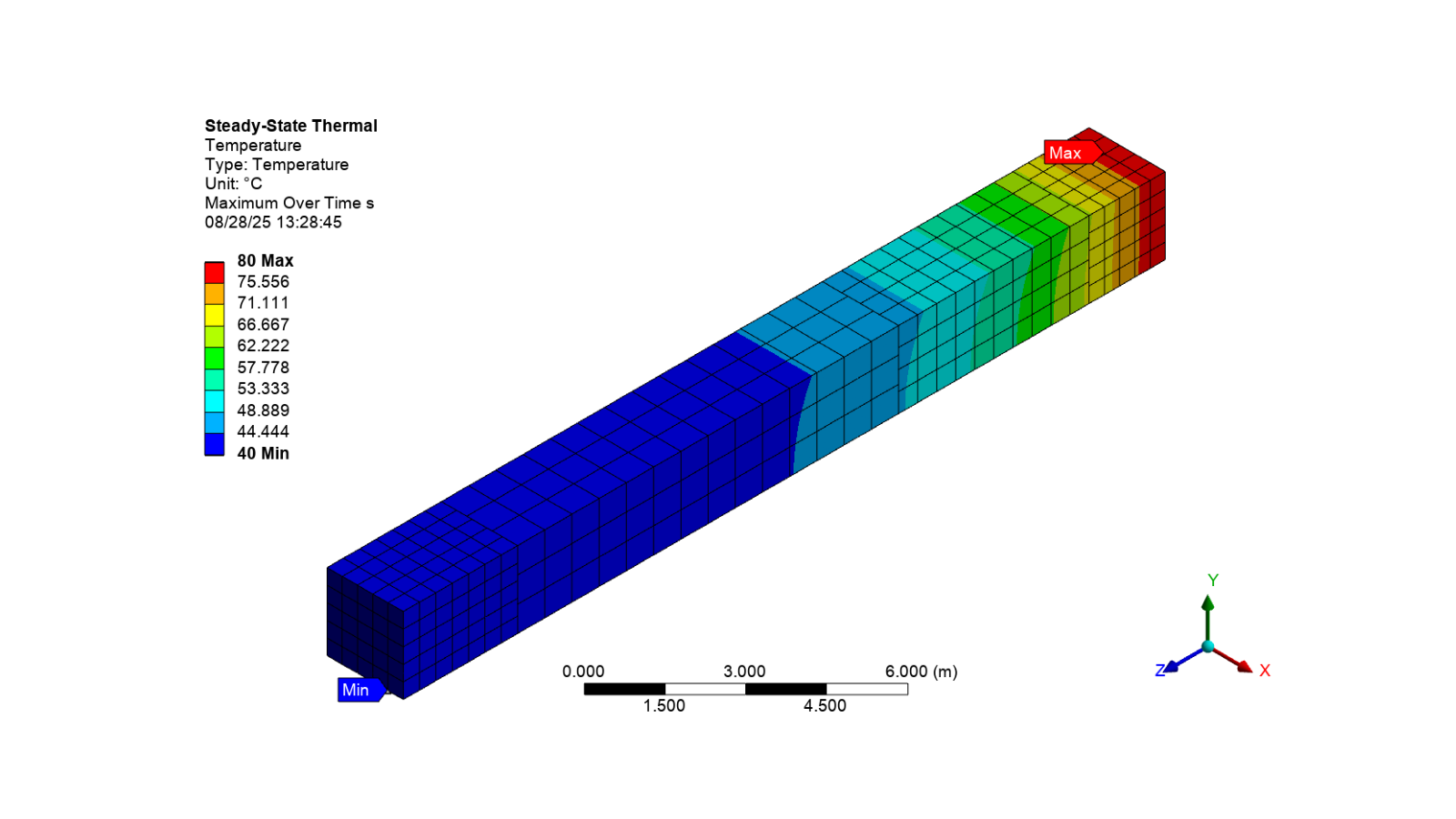

Add temperature results to the solution

# Get the solution object for the steady state thermal analysis

stat_therm_soln = model.Analyses[0].Solution

# Add four temperature results to the solution

temp_rst = stat_therm_soln.AddTemperature()

temp_rst.By = SetDriverStyle.MaximumOverTime

# Set the temperature location to the body1 named selection

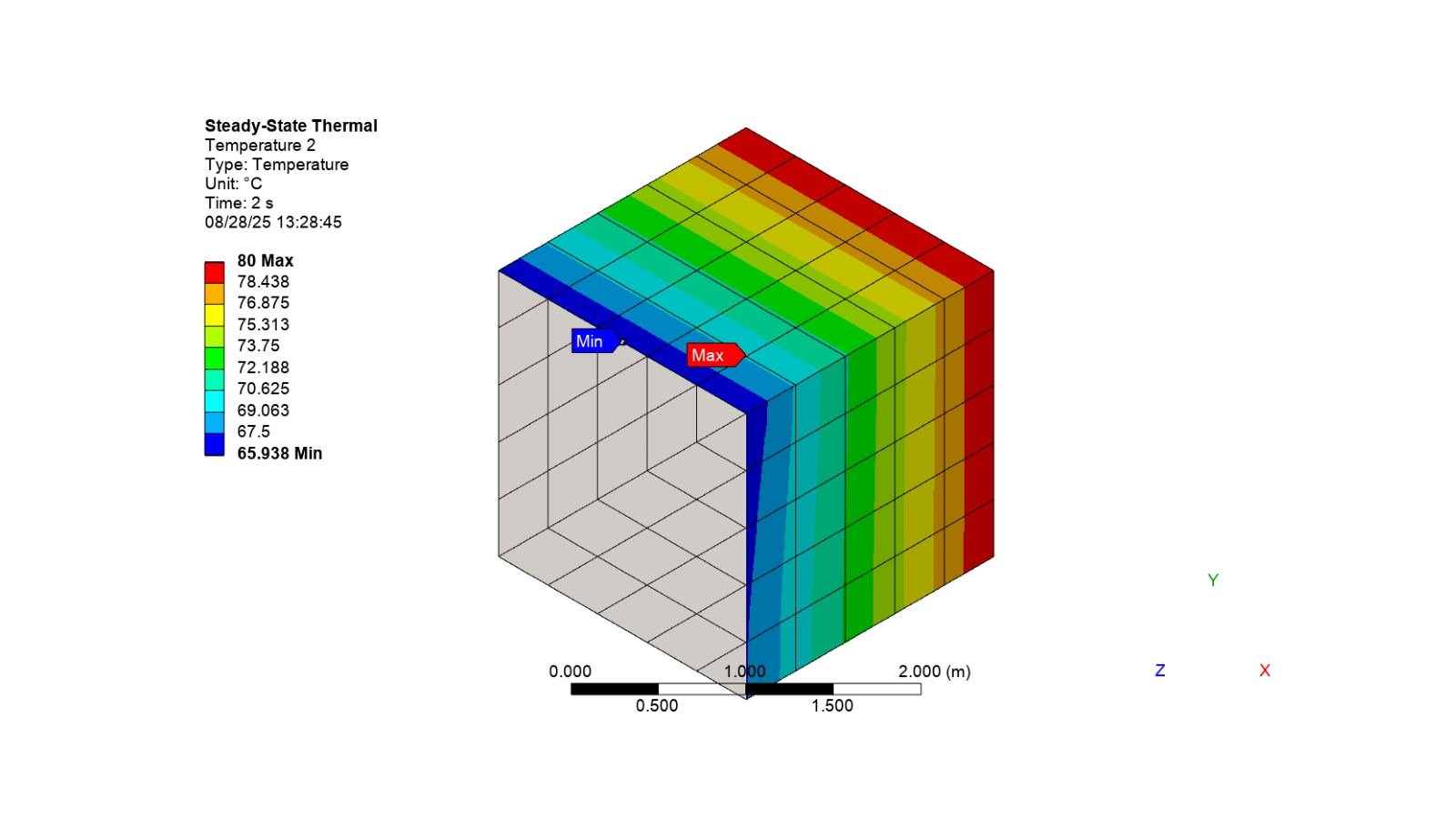

temp_rst2 = stat_therm_soln.AddTemperature()

temp_rst2.Location = body1

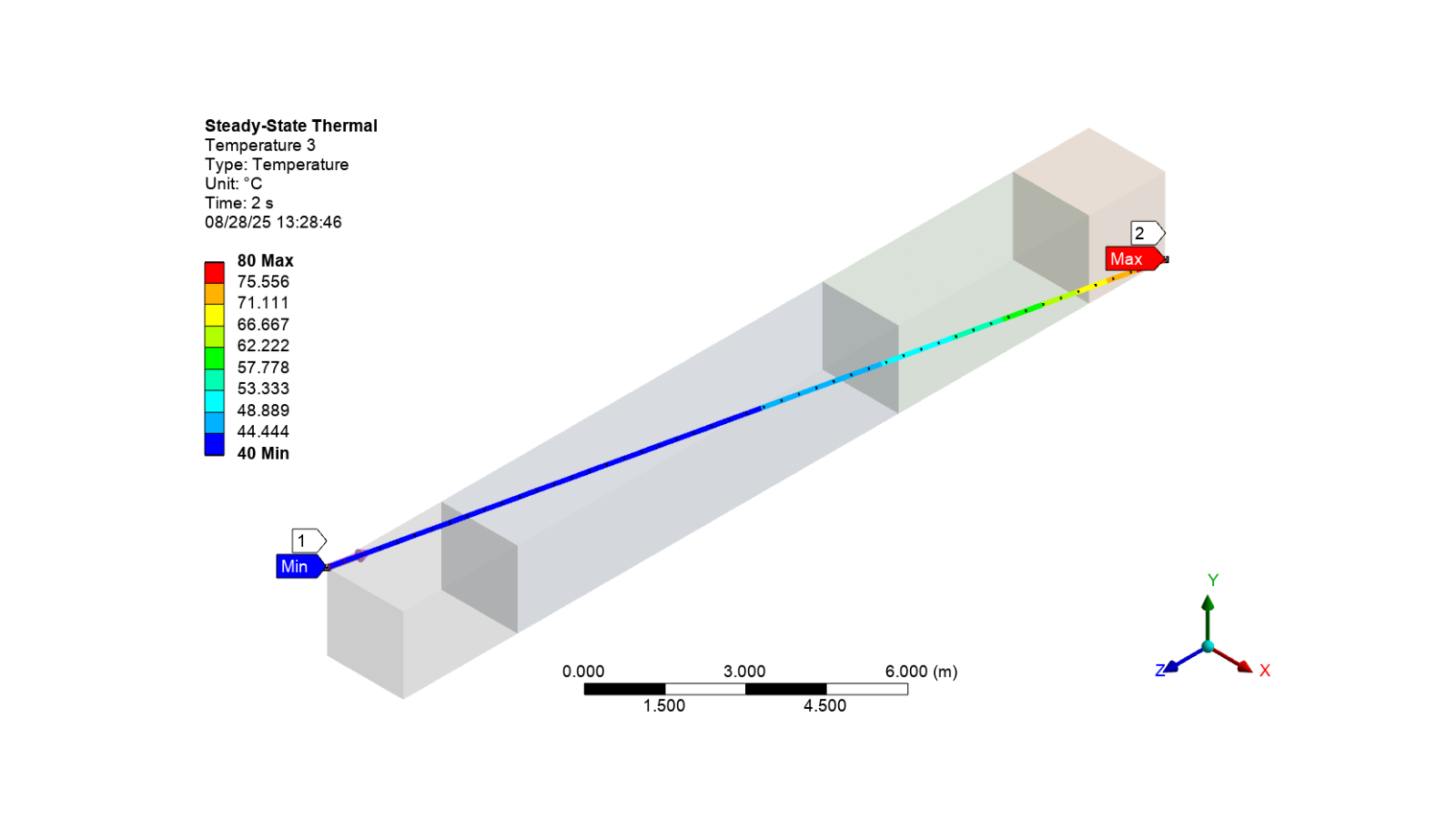

# Set the temperature location to the construction geometry path

temp_rst3 = stat_therm_soln.AddTemperature()

temp_rst3.Location = construction_geom_path

# Set the temperaature location to the construction geometry surface

temp_rst4 = stat_therm_soln.AddTemperature()

temp_rst4.Location = surface

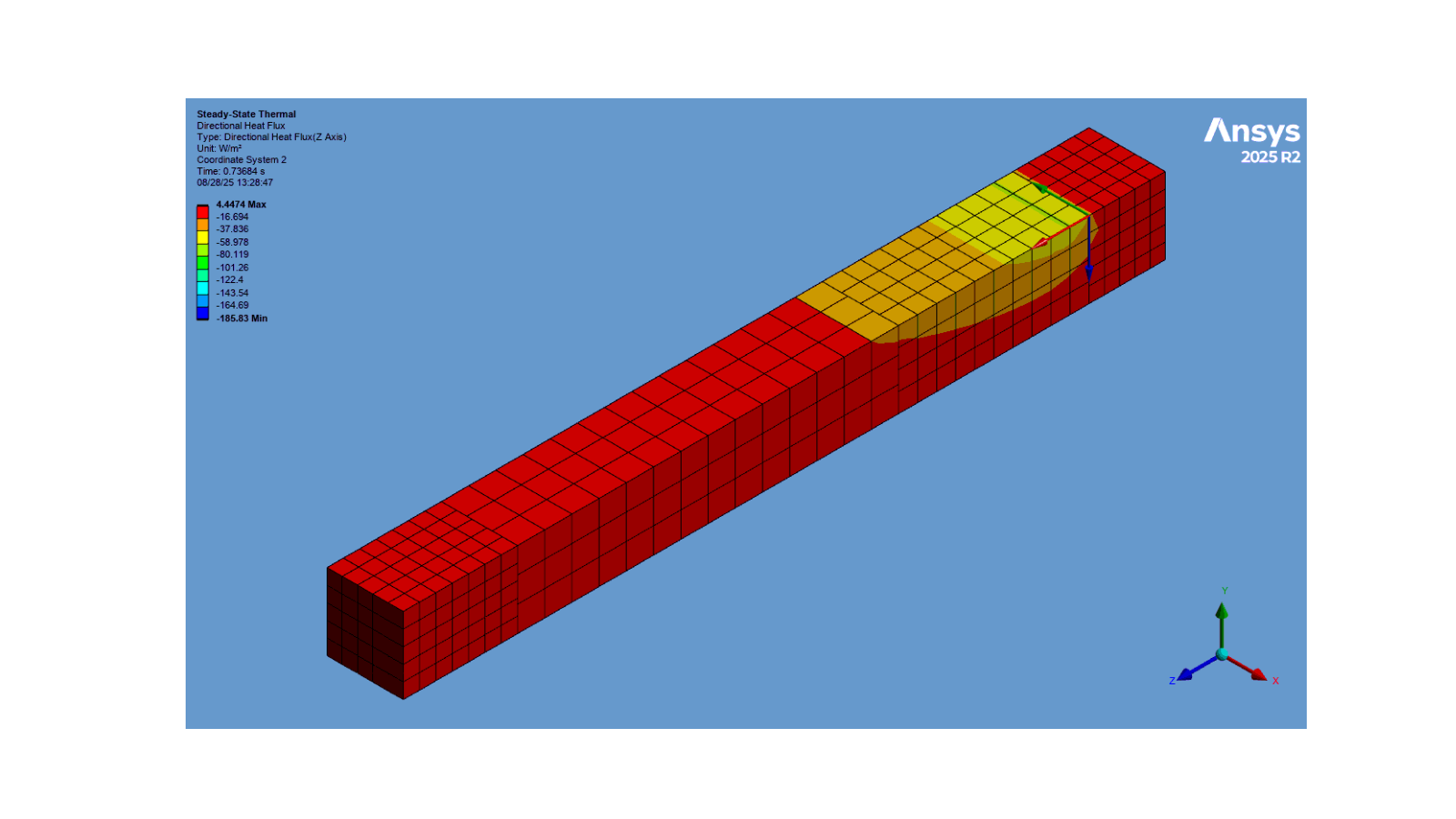

Add the total and directional heat flux to the solution

total_heat_flux = stat_therm_soln.AddTotalHeatFlux()

directional_heat_flux = stat_therm_soln.AddTotalHeatFlux()

# Set the thermal result type and normal orientation for the directional heat flux

directional_heat_flux.ThermalResultType = TotalOrDirectional.Directional

directional_heat_flux.NormalOrientation = NormalOrientationType.ZAxis

# Set the coordinate system's primary axis for the directional heat flux

lcs2.PrimaryAxisDefineBy = CoordinateSystemAlignmentType.GlobalZ

directional_heat_flux.CoordinateSystem = lcs2

# Set the display option for the directional heat flux

directional_heat_flux.DisplayOption = ResultAveragingType.Averaged

Add thermal error and temperature probes

# Add a thermal error to the solution

thermal_error = stat_therm_soln.AddThermalError()

# Add a temperature probe to the solution

temp_probe = stat_therm_soln.AddTemperatureProbe()

# Set the temperature probe location to the face1 named selection

temp_probe.GeometryLocation = face1

# Set the temperature probe location method to the coordinate system

temp_probe.LocationMethod = LocationDefinitionMethod.CoordinateSystem

temp_probe.CoordinateSystemSelection = lcs2

Add a heat flux probe

hflux_probe = stat_therm_soln.AddHeatFluxProbe()

# Set the location method for the heat flux probe

hflux_probe.LocationMethod = LocationDefinitionMethod.CoordinateSystem

# Set the coordinate system for the heat flux probe

hflux_probe.CoordinateSystemSelection = lcs2

# Set the result selection to the z-axis for the heat flux probe

hflux_probe.ResultSelection = ProbeDisplayFilter.ZAxis

Add a reaction probe

# Update the analysis settings to allow output control nodal forces

analysis_settings.NodalForces = OutputControlsNodalForcesType.Yes

# Add a reaction probe to the solution

reaction_probe = stat_therm_soln.AddReactionProbe()

# Set the reaction probe geometry location to the face1 named selection

reaction_probe.LocationMethod = LocationDefinitionMethod.GeometrySelection

reaction_probe.GeometryLocation = face1

Add a radiation probe

radiation_probe = stat_therm_soln.AddRadiationProbe()

# Set the radiation probe boundary condition to the radiation boundary condition

radiation_probe.BoundaryConditionSelection = radiation

# Display all results for the radiation probe

radiation_probe.ResultSelection = ProbeDisplayFilter.All

Solve the solution#

# Solve the steady state thermal analysis solution

stat_therm_soln.Solve(True)

Show messages#

# Print all messages from Mechanical

app.messages.show()

Severity: Warning

DisplayString: A result is scoped to a construction geometry object which might have points shared with multiple bodies. Please check the results. Object=Surface Result=Temperature 4

Severity: Info

DisplayString: The requested license was received from the License Manager after 34 seconds.

Display the results#

# Activate the total body temperature and display the image

app.Tree.Activate([temp_rst])

set_camera_and_display_image(camera, graphics, settings_720p, output_path, "total_body_temp.png")

Temperature on part of the body

# Activate the temperature on part of the body and display the image

app.Tree.Activate([temp_rst2])

set_camera_and_display_image(camera, graphics, settings_720p, output_path, "part_temp_body.png")

Temperature distribution along the specific path

# Activate the temperature distribution along the specific path and display the image

app.Tree.Activate([temp_rst3])

set_camera_and_display_image(

camera, graphics, settings_720p, output_path, "path_temp_distribution.png"

)

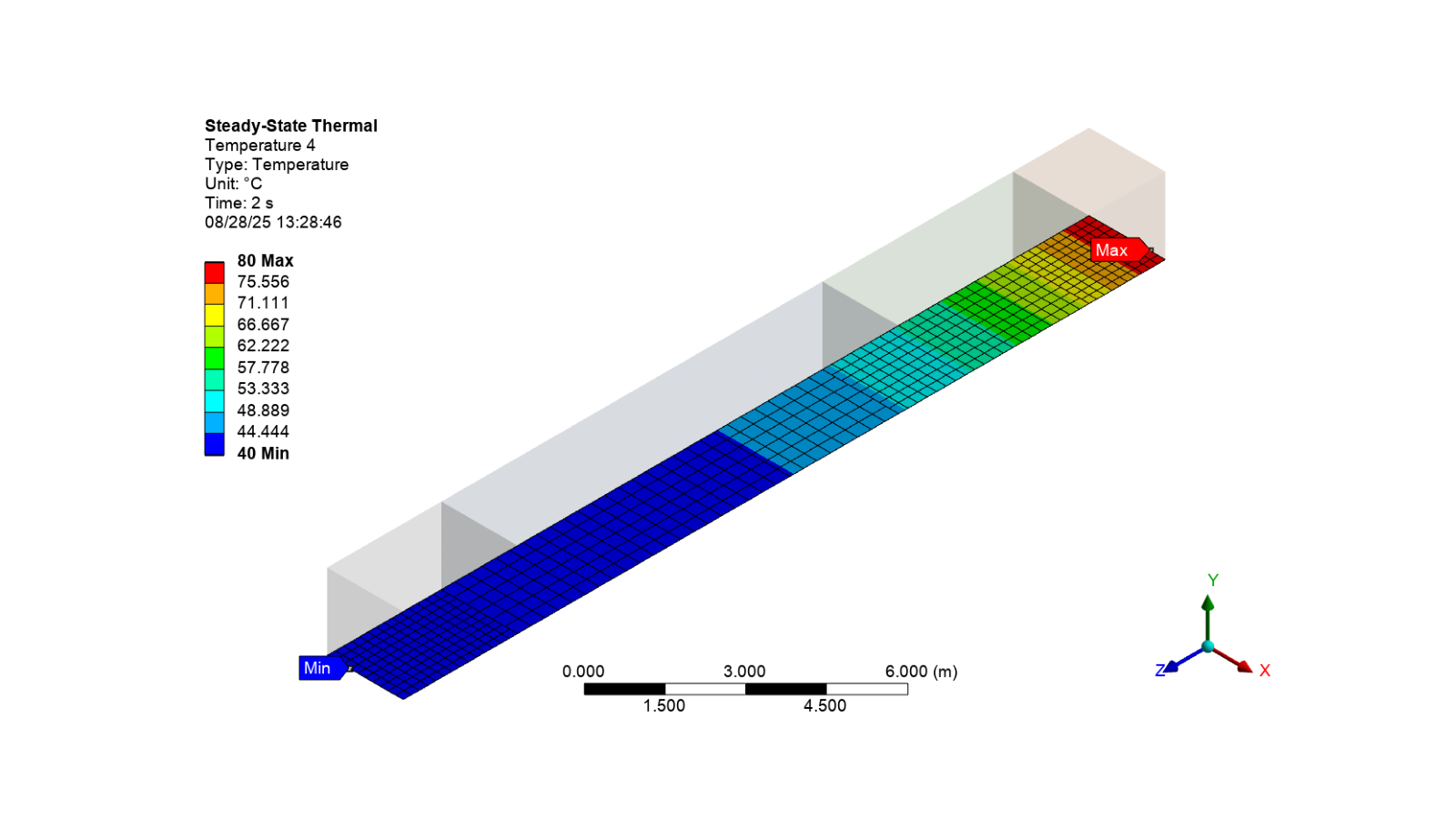

Temperature of bottom surface

# Activate the temperature of the bottom surface and display the image

app.Tree.Activate([temp_rst4])

set_camera_and_display_image(

camera, graphics, settings_720p, output_path, "bottom_surface_temp.png"

)

Export the directional heat flux animation#

Create a function to update the animation frames

def update_animation(frame: int) -> list[mpimg.AxesImage]:

"""Update the animation frame for the GIF.

Parameters

----------

frame : int

The frame number to update the animation.

Returns

-------

list[mpimg.AxesImage]

A list containing the updated image for the animation.

"""

# Seeks to the given frame in this sequence file

gif.seek(frame)

# Set the image array to the current frame of the GIF

image.set_data(gif.convert("RGBA"))

# Return the updated image

return [image]

Show the directional heat flux animation

# Activate the directional heat flux

app.Tree.Activate([directional_heat_flux])

# Set the animation export format and settings

animation_export_format = Ansys.Mechanical.DataModel.Enums.GraphicsAnimationExportFormat.GIF

settings_720p = Ansys.Mechanical.Graphics.AnimationExportSettings()

settings_720p.Width = 1280

settings_720p.Height = 720

# Export the directional heat flux animation as a GIF

directional_heat_flux_gif = output_path / "directional_heat_flux.gif"

directional_heat_flux.ExportAnimation(

str(directional_heat_flux_gif), animation_export_format, settings_720p

)

# Open the GIF file and create an animation

gif = Image.open(directional_heat_flux_gif)

# Set the subplots for the animation and turn off the axis

figure, axes = plt.subplots(figsize=(16, 9))

axes.axis("off")

# Change the color of the image

image = axes.imshow(gif.convert("RGBA"))

# Create the animation using the figure, update_animation function, and the GIF frames

# Set the interval between frames to 200 milliseconds and repeat the animation

ani = FuncAnimation(

figure,

update_animation,

frames=range(gif.n_frames),

interval=100,

repeat=True,

blit=True,

)

# Show the animation

plt.show()

Display the output file from the solve#

# Get the working directory for the steady state thermal analysis

solve_path = Path(stat_therm.WorkingDir)

# Get the path to the solve.out file

solve_out_path = solve_path / "solve.out"

# Print the output of the solve.out file if applicable

if solve_out_path:

with solve_out_path.open("rt") as file:

for line in file:

print(line, end="")

Ansys Mechanical Enterprise

*------------------------------------------------------------------*

| |

| W E L C O M E T O T H E A N S Y S (R) P R O G R A M |

| |

*------------------------------------------------------------------*

***************************************************************

* ANSYS MAPDL 2026 R1 LEGAL NOTICES *

***************************************************************

* *

* Copyright (c) 2026 Synopsys, Inc. and ANSYS, Inc. *

* All rights reserved. *

* Unauthorized use, distribution or duplication is *

* prohibited. *

* *

* Ansys is a registered trademark of Ansys, Inc. or its *

* subsidiaries in the United States or other countries. *

* See the Ansys, Inc. online documentation or the Ansys, Inc. *

* documentation CD or online help for the complete Legal *

* Notice. *

* *

***************************************************************

* *

* THIS ANSYS SOFTWARE PRODUCT AND PROGRAM DOCUMENTATION *

* INCLUDE TRADE SECRETS AND CONFIDENTIAL AND PROPRIETARY *

* PRODUCTS OF ANSYS, INC., ITS SUBSIDIARIES, OR LICENSORS. *

* The software products and documentation are furnished by *

* Ansys, Inc. or its subsidiaries under a software license *

* agreement that contains provisions concerning *

* non-disclosure, copying, length and nature of use, *

* compliance with exporting laws, warranties, disclaimers, *

* limitations of liability, and remedies, and other *

* provisions. The software products and documentation may be *

* used, disclosed, transferred, or copied only in accordance *

* with the terms and conditions of that software license *

* agreement. *

* *

* Ansys, Inc. is a UL registered *

* ISO 9001:2015 company. *

* *

***************************************************************

* *

* This product is subject to U.S. laws governing export and *

* re-export. *

* *

* For U.S. Government users, except as specifically granted *

* by the Ansys, Inc. software license agreement, the use, *

* duplication, or disclosure by the United States Government *

* is subject to restrictions stated in the Ansys, Inc. *

* software license agreement and FAR 12.212 (for non-DOD *

* licenses). *

* *

***************************************************************

2026 R1

Point Releases and Patches installed:

Ansys, Inc. License Manager 2026 R1

LS-DYNA 2026 R1

Core WB Files 2026 R1

Mechanical Products 2026 R1

***** MAPDL COMMAND LINE ARGUMENTS *****

BATCH MODE REQUESTED (-b) = NOLIST

INPUT FILE COPY MODE (-c) = COPY

DISTRIBUTED MEMORY PARALLEL REQUESTED

4 PARALLEL PROCESSES REQUESTED WITH SINGLE THREAD PER PROCESS

TOTAL OF 4 CORES REQUESTED

INPUT FILE NAME = /github/home/.mw/Application Data/Ansys/v261/AnsysMechC4C6/Project_Mech_Files/SteadyStateThermal/dummy.dat

OUTPUT FILE NAME = /github/home/.mw/Application Data/Ansys/v261/AnsysMechC4C6/Project_Mech_Files/SteadyStateThermal/solve.out

START-UP FILE MODE = NOREAD

STOP FILE MODE = NOREAD

RELEASE= 2026 R1 BUILD= 26.1 UP20260112 VERSION=LINUX x64

CURRENT JOBNAME=file0 22:14:39 JAN 27, 2026 Elapsed Time= 0.238

PARAMETER _DS_PROGRESS = 999.0000000

/INPUT FILE= ds.dat LINE= 0

*** NOTE *** ELAPSED TIME = 0.667 TIME= 22:14:39

The /CONFIG,NOELDB command is not valid in a distributed memory

parallel solution. Command is ignored.

*GET _WALLSTRT FROM ACTI ITEM=TIME WALL VALUE= 0.186144553E-03

TITLE=

--Steady-State Thermal

SET PARAMETER DIMENSIONS ON _WB_PROJECTSCRATCH_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_PROJECTSCRATCH_DIR(1) = /github/home/.mw/Application Data/Ansys/v261/AnsysMechC4C6/Project_Mech_Files/SteadyStateThermal/

SET PARAMETER DIMENSIONS ON _WB_SOLVERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_SOLVERFILES_DIR(1) = /github/home/.mw/Application Data/Ansys/v261/AnsysMechC4C6/Project_Mech_Files/SteadyStateThermal/

SET PARAMETER DIMENSIONS ON _WB_USERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_USERFILES_DIR(1) = /github/home/.mw/Application Data/Ansys/v261/AnsysMechC4C6/Project_Mech_Files/UserFiles/

--- Data in consistent MKS units. See Solving Units in the help system for more

MKS UNITS SPECIFIED FOR INTERNAL

LENGTH (l) = METER (M)

MASS (M) = KILOGRAM (KG)

TIME (t) = SECOND (SEC)

TEMPERATURE (T) = CELSIUS (C)

TOFFSET = 273.0

CHARGE (Q) = COULOMB

FORCE (f) = NEWTON (N) (KG-M/SEC2)

HEAT = JOULE (N-M)

PRESSURE = PASCAL (NEWTON/M**2)

ENERGY (W) = JOULE (N-M)

POWER (P) = WATT (N-M/SEC)

CURRENT (i) = AMPERE (COULOMBS/SEC)

CAPACITANCE (C) = FARAD

INDUCTANCE (L) = HENRY

MAGNETIC FLUX = WEBER

RESISTANCE (R) = OHM

ELECTRIC POTENTIAL = VOLT

INPUT UNITS ARE ALSO SET TO MKS

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2026 R1 26.1 ***

Ansys Mechanical Enterprise

00000000 VERSION=LINUX x64 22:14:39 JAN 27, 2026 Elapsed Time= 0.671

--Steady-State Thermal

***** MAPDL ANALYSIS DEFINITION (PREP7) *****

*********** Send User Defined Coordinate System(s) ***********

*********** Nodes for the whole assembly ***********

*********** Elements for Body 1 'Part4' ***********

*********** Elements for Body 2 'Part3' ***********

*********** Elements for Body 3 'Part2' ***********

*********** Elements for Body 4 'Part1' ***********

*********** Send Materials ***********

*********** Create Contact "Contact Region" ***********

Real Constant Set For Above Contact Is 6 & 5

*********** Create Contact "Contact Region 2" ***********

Real Constant Set For Above Contact Is 8 & 7

*********** Create Contact "Contact Region 3" ***********

Real Constant Set For Above Contact Is 10 & 9

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Define Temperature Constraint ***********

*********** Define Temperature Constraint ***********

*********** Create "ToSurface(Open)" Radiation ***********

***************** Define Uniform Initial temperature ***************

***** ROUTINE COMPLETED ***** ELAPSED TIME = 0.679

--- Number of total nodes = 685

--- Number of contact elements = 48

--- Number of spring elements = 0

--- Number of bearing elements = 0

--- Number of solid elements = 80

--- Number of condensed parts = 0

--- Number of total elements = 128

*GET _WALLBSOL FROM ACTI ITEM=TIME WALL VALUE= 0.188593833E-03

****************************************************************************

************************* SOLUTION ********************************

****************************************************************************

***** MAPDL SOLUTION ROUTINE *****

PERFORM A STATIC ANALYSIS

THIS WILL BE A NEW ANALYSIS

CONTACT INFORMATION PRINTOUT LEVEL 1

CHECK INITIAL OPEN/CLOSED STATUS OF SELECTED CONTACT ELEMENTS

AND LIST DETAILED CONTACT PAIR INFORMATION

SPLIT CONTACT SURFACES AT SOLVE PHASE

NUMBER OF SPLITTING TBD BY PROGRAM

DO NOT SAVE ANY RESTART FILES AT ALL

DO NOT COMBINE ELEMENT MATRIX FILES (.emat) AFTER DISTRIBUTED PARALLEL SOLUTION

DO NOT COMBINE ELEMENT SAVE DATA FILES (.esav) AFTER DISTRIBUTED PARALLEL SOLUTION

****************************************************

******************* SOLVE FOR LS 1 OF 2 ****************

SPECIFIED CONSTRAINT TEMP FOR PICKED NODES

SET ACCORDING TO TABLE PARAMETER = _LOADVARI63

SPECIFIED CONSTRAINT TEMP FOR PICKED NODES

SET ACCORDING TO TABLE PARAMETER = _LOADVARI65

SPECIFIED SURFACE LOAD RDSF FOR ALL PICKED ELEMENTS LKEY = 6 KVAL = 1

VALUES = 1.0000 1.0000 1.0000 1.0000

SPECIFIED SURFACE LOAD RDSF FOR ALL PICKED ELEMENTS LKEY = 6 KVAL = 2

VALUES = 1.0000 1.0000 1.0000 1.0000

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 685 STEP 1

685 NODES (OF 685 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 320 STEP 1

128 ELEMENTS (OF 128 DEFINED) SELECTED BY ESEL COMMAND.

SPECIFIED CONSTRAINT TEMP FOR PICKED NODES

SET ACCORDING TO TABLE PARAMETER = _LOADVARI67

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 685 STEP 1

685 NODES (OF 685 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 320 STEP 1

128 ELEMENTS (OF 128 DEFINED) SELECTED BY ESEL COMMAND.

PRINTOUT RESUMED BY /GOP

USE AUTOMATIC TIME STEPPING THIS LOAD STEP

USE 1 SUBSTEPS INITIALLY THIS LOAD STEP FOR ALL DEGREES OF FREEDOM

FOR AUTOMATIC TIME STEPPING:

USE 10 SUBSTEPS AS A MAXIMUM

USE 1 SUBSTEPS AS A MINIMUM

TIME= 1.0000

ERASE THE CURRENT DATABASE OUTPUT CONTROL TABLE.

WRITE ALL ITEMS TO THE DATABASE WITH A FREQUENCY OF NONE

FOR ALL APPLICABLE ENTITIES

WRITE NSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE RSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EANG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE VENG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE FFLU ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE CONT ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE NLOA ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE MISC ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

CONVERGENCE ON HEAT BASED ON THE NORM OF THE N-R LOAD

WITH A TOLERANCE OF 0.1000E-03 AND A MINIMUM REFERENCE VALUE OF 0.1000E-05

USING THE L2 NORM (CHECK THE SRSS VALUE)

UNDER RELAXATION FOR RADIATION FLUX= 0.10000

TOLERENCE FOR RADIOSITY FLUX= 0.00010

USING JACOBI ITERATIVE SOLVER FOR RADIOSITY SOLUTION

FOR 3D ENCLOSURES.

USING GSEIDEL ITERATIVE SOLVER FOR RADIOSITY SOLUTION

FOR 2D ENCLOSURES.

MAXIMUM NUMBER OF ITERATIONS= 1000

TOLERENCE FOR ITERATIVE SOLVER= 0.10000

RELAXATION FOR ITERATIVE SOLVER= 0.10000

HEMICUBE RESOLUTION= 10

MIN NORMALIZED DIST BEFORE AUTO SUBDIVIDE= 1.000000000E-06

SELECT COMPONENT _CM67

SELECT ALL ELEMENTS HAVING ANY NODE IN NODAL SET.

46 ELEMENTS (OF 128 DEFINED) SELECTED FROM

130 SELECTED NODES BY ESLN COMMAND.

BEFORE SYMMETRIZATION:

NUMBER OF RADIATION NODES CREATED = 51

NUMBER OF RADIOSITY SURFACE ELEMENTS CREATED = 30

AFTER SYMMETRIZATION:

FULL NUMBER OF RADIATION NODES CREATED = 51

FULL NUMBER OF RADIOSITY SURFACE ELEMENTS CREATED = 30

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 736 STEP 1

736 NODES (OF 736 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 350 STEP 1

158 ELEMENTS (OF 158 DEFINED) SELECTED BY ESEL COMMAND.

*GET ANSINTER_ FROM ACTI ITEM=INT VALUE= 0.00000000

*IF ANSINTER_ ( = 0.00000 ) NE

0 ( = 0.00000 ) THEN

*ENDIF

*** NOTE *** ELAPSED TIME = 0.690 TIME= 22:14:39

The automatic domain decomposition logic has selected the MESH domain

decomposition method with 4 processes per solution.

***** MAPDL SOLVE COMMAND *****

CALCULATING VIEW FACTORS USING HEMICUBE METHOD

RETRIEVED 1 ENCLOSURES.

TOTAL OF 30 DEFINED ELEMENT FACES.

# ENCLOSURE = 1 # SURFACES = 30 # NODES = 51

ELAPSED TIME OF CALCULATION FOR THIS ENCLOSURE = 0.480870E-03

CHECKING VIEW FACTOR SUM

*** NOTE *** ELAPSED TIME = 0.694 TIME= 22:14:39

Some of the rows in the viewfactor matrix have all zeros for enclosure

1.

VIEW FACTOR CALCULATION COMPLETE

WRITING VIEW FACTORS TO FILE file0.vf

VIEW FACTORS WERE WRITTEN TO FILE file0.vf

*** WARNING *** ELAPSED TIME = 0.695 TIME= 22:14:39

Element shape checking is currently inactive. Issue SHPP,ON or

SHPP,WARN to reactivate, if desired.

*** NOTE *** ELAPSED TIME = 0.695 TIME= 22:14:39

The model data was checked and warning messages were found.

Please review output or errors file ( /github/home/.mw/Application

Data/Ansys/v261/AnsysMechC4C6/Project_Mech_Files/SteadyStateThermal/fil

le0.err ) for these warning messages.

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2026 R1 26.1 ***

Ansys Mechanical Enterprise

00000000 VERSION=LINUX x64 22:14:39 JAN 27, 2026 Elapsed Time= 0.696

--Steady-State Thermal

S O L U T I O N O P T I O N S

PROBLEM DIMENSIONALITY. . . . . . . . . . . . .3-D

DEGREES OF FREEDOM. . . . . . TEMP

ANALYSIS TYPE . . . . . . . . . . . . . . . . .STATIC (STEADY-STATE)

OFFSET TEMPERATURE FROM ABSOLUTE ZERO . . . . . 273.15

GLOBALLY ASSEMBLED MATRIX . . . . . . . . . . .SYMMETRIC

*** NOTE *** ELAPSED TIME = 0.696 TIME= 22:14:39

This nonlinear analysis defaults to using the full Newton-Raphson

solution procedure. This can be modified using the NROPT command.

*** NOTE *** ELAPSED TIME = 0.696 TIME= 22:14:39

The conditions for direct assembly have been met. No .emat or .erot

files will be produced.

TRIM CONTACT/TARGET SURFACE

START TRIMMING SMALL/BONDED CONTACT PAIRS FOR DMP RUN.

12 CONTACT ELEMENTS & 12 TARGET ELEMENTS ARE DELETED DUE TO TRIMMING LOGIC.

3 CONTACT PAIRS ARE REMOVED.

CHECK INITIAL OPEN/CLOSED STATUS OF SELECTED CONTACT ELEMENTS

AND LIST DETAILED CONTACT PAIR INFORMATION

*** NOTE *** ELAPSED TIME = 0.704 TIME= 22:14:39

The largest contact pair has few number of contact elements than the

optimal domain size for the specified number of CPU domains. As a

result, no contact pairs were split.

*** NOTE *** ELAPSED TIME = 0.704 TIME= 22:14:39

The maximum number of contact elements in any single contact pair is 4,

which is smaller than the optimal domain size of 120 elements for the

given number of CPU domains (4). Therefore, no contact pairs are

being split by the CNCH,DMP logic.

*** NOTE *** ELAPSED TIME = 0.706 TIME= 22:14:39

Deformable-deformable contact pair identified by real constant set 5

and contact element type 5 has been set up.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 1.0000

Average contact pair depth 1.0000

Average target surface length 1.0000

Default pinball region factor PINB 0.25000

The resulting pinball region 0.25000

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 29952.

Heat radiation is excluded.

*** NOTE *** ELAPSED TIME = 0.706 TIME= 22:14:39

Max. Initial penetration 3.552713679E-15 was detected between contact

element 279 and target element 288.

****************************************

*** NOTE *** ELAPSED TIME = 0.706 TIME= 22:14:39

Deformable-deformable contact pair identified by real constant set 7

and contact element type 7 has been set up.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 1.0000

Average contact pair depth 1.0000

Average target surface length 1.0000

Default pinball region factor PINB 0.25000

The resulting pinball region 0.25000

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 29952.

Heat radiation is excluded.

*** NOTE *** ELAPSED TIME = 0.706 TIME= 22:14:39

Max. Initial penetration 1.776356839E-15 was detected between contact

element 295 and target element 304.

****************************************

*** NOTE *** ELAPSED TIME = 0.706 TIME= 22:14:39

Deformable-deformable contact pair identified by real constant set 9

and contact element type 9 has been set up.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 1.0000

Average contact pair depth 1.0000

Average target surface length 1.0000

Default pinball region factor PINB 0.25000

The resulting pinball region 0.25000

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 29952.

Heat radiation is excluded.

*** NOTE *** ELAPSED TIME = 0.707 TIME= 22:14:39

Max. Initial penetration 4.440892099E-16 was detected between contact

element 309 and target element 318.

****************************************

D I S T R I B U T E D D O M A I N D E C O M P O S E R

...Number of elements: 134

...Number of nodes: 736

...Decompose to 4 CPU domains

...Element load balance ratio = 1.133

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 1

TIME AT END OF THE LOAD STEP. . . . . . . . . . 1.0000

AUTOMATIC TIME STEPPING . . . . . . . . . . . . ON

INITIAL NUMBER OF SUBSTEPS . . . . . . . . . 1

MAXIMUM NUMBER OF SUBSTEPS . . . . . . . . . 10

MINIMUM NUMBER OF SUBSTEPS . . . . . . . . . 1

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS. . . . 15

STEP CHANGE BOUNDARY CONDITIONS . . . . . . . . NO

TERMINATE ANALYSIS IF NOT CONVERGED . . . . . .YES (EXIT)

CONVERGENCE CONTROLS

LABEL REFERENCE TOLERANCE NORM MINREF

HEAT 0.000 0.1000E-03 2 0.1000E-05

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS

ITEM FREQUENCY COMPONENT

ALL NONE

NSOL ALL

RSOL ALL

EANG ALL

VENG ALL

FFLU ALL

CONT ALL

NLOA ALL

MISC ALL

SOLUTION MONITORING INFO IS WRITTEN TO FILE= file.mntr

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS HAS BEEN MODIFIED

TO BE, NEQIT = 1000, BY SOLUTION CONTROL LOGIC.

RADIOSITY SOLVER CALCULATION

ENCLOSURE NUMBER= 1

RADIOSITY SOLVER CONVERGED AFTER 59 ITERATIONS

ELAPSED TIME OF RADIOSITY SOLVER FOR ENCLOSURE= 0.548620E-03

RAD FLUX CONVERGENCE VALUE= 1.00000 CRITERION= 0.100000E-03

**** CENTER OF MASS, MASS, AND MASS MOMENTS OF INERTIA ****

CALCULATIONS ASSUME ELEMENT MASS AT ELEMENT CENTROID

TOTAL MASS = 0.62800E+06

MOM. OF INERTIA MOM. OF INERTIA

CENTER OF MASS ABOUT ORIGIN ABOUT CENTER OF MASS

XC = 1.0000 IXX = 0.8447E+08 IXX = 0.2104E+08

YC = 1.0000 IYY = 0.8447E+08 IYY = 0.2104E+08

ZC = 10.000 IZZ = 0.1570E+07 IZZ = 0.3140E+06

IXY = -0.6280E+06 IXY = -0.1164E-09

IYZ = -0.6280E+07 IYZ = -0.9313E-09

IZX = -0.6280E+07 IZX = 0.000

*** MASS SUMMARY BY ELEMENT TYPE ***

TYPE MASS

1 94200.0

2 314000.

3 157000.

4 62800.0

Range of element maximum matrix coefficients in global coordinates

Maximum = 4437.32788 at element 295.

Minimum = 58.9111111 at element 77.

*** ELEMENT MATRIX FORMULATION TIMES

TYPE NUMBER ENAME TOTAL ELAPSED AVG ELAPSED

1 12 SOLID279 0.0008 0.000062517

2 40 SOLID279 0.0025 0.000061683

3 20 SOLID279 0.0013 0.000064389

4 8 SOLID279 0.0007 0.000081485

5 4 CONTA174 0.0008 0.000206246

6 4 TARGE170 0.0000 0.000002422

7 4 CONTA174 0.0009 0.000224988

8 4 TARGE170 0.0000 0.000002340

9 4 CONTA174 0.0008 0.000209358

10 4 TARGE170 0.0000 0.000002358

11 30 SURF252 0.0006 0.000019269

Elapsed Time at end of element matrix formulation = 0.737485.

HT FLOW CONVERGENCE VALUE= 8798. CRITERION= 0.8843

DISTRIBUTED SPARSE MATRIX DIRECT SOLVER.

Number of equations = 642, Maximum wavefront = 81

Memory allocated on only this MPI rank (rank 0)

-------------------------------------------------------------------

Equation solver memory allocated = 0.471 MB

Equation solver memory required for in-core mode = 0.452 MB

Equation solver memory required for out-of-core mode = 0.452 MB

Total (solver and non-solver) memory allocated = 511.240 MB

Total memory summed across all MPI ranks on this machines

-------------------------------------------------------------------

Equation solver memory allocated = 1.820 MB

Equation solver memory required for in-core mode = 1.747 MB

Equation solver memory required for out-of-core mode = 1.747 MB

Total (solver and non-solver) memory allocated = 1226.734 MB

*** NOTE *** ELAPSED TIME = 0.744 TIME= 22:14:39

The Distributed Sparse Matrix Solver is currently running in the

in-core memory mode. This memory mode uses the most amount of memory

in order to avoid using the hard drive as much as possible, which most

often results in the fastest solution time. This mode is recommended

if enough physical memory is present to accommodate all of the solver

data.

Distributed sparse solver maximum pivot= 3927.02875 at node 601 TEMP.

Distributed sparse solver minimum pivot= 28.858917 at node 480 TEMP.

Distributed sparse solver minimum pivot in absolute value= 28.858917 at

node 480 TEMP.

EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 28.00

HT FLOW CONVERGENCE VALUE= 0.1289E-08 CRITERION= 0.9751E-01 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 1

RADIOSITY SOLVER CALCULATION

ENCLOSURE NUMBER= 1

RADIOSITY SOLVER CONVERGED AFTER 48 ITERATIONS

ELAPSED TIME OF RADIOSITY SOLVER FOR ENCLOSURE= 0.449800E-03

RAD FLUX CONVERGENCE VALUE= 0.153457 CRITERION= 0.100000E-03

HT FLOW CONVERGENCE VALUE= 8.665 CRITERION= 0.9782E-01

EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.1706

HT FLOW CONVERGENCE VALUE= 0.1450E-08 CRITERION= 0.9799E-01 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 2

RADIOSITY SOLVER CALCULATION

ENCLOSURE NUMBER= 1

RADIOSITY SOLVER CONVERGED AFTER 1 ITERATIONS

ELAPSED TIME OF RADIOSITY SOLVER FOR ENCLOSURE= 0.400800E-04

RAD FLUX CONVERGENCE VALUE= 0.553465E-04 CRITERION= 0.100000E-03

RADIOSITY FLUX CONVERGED AFTER ITERATION= 3 SUBSTEP= 1

HT FLOW CONVERGENCE VALUE= 2.851 CRITERION= 0.9966E-01

EQUIL ITER 3 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.6787E-01

HT FLOW CONVERGENCE VALUE= 0.1935E-08 CRITERION= 0.9972E-01 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 3

*** ELEMENT RESULT CALCULATION TIMES

TYPE NUMBER ENAME TOTAL ELAPSED AVG ELAPSED

1 12 SOLID279 0.0004 0.000031284

2 40 SOLID279 0.0018 0.000045222

3 20 SOLID279 0.0008 0.000039200

4 8 SOLID279 0.0004 0.000052379

5 4 CONTA174 0.0003 0.000068894

7 4 CONTA174 0.0003 0.000069905

9 4 CONTA174 0.0003 0.000071457

11 30 SURF252 0.0004 0.000013744

*** NODAL LOAD CALCULATION TIMES

TYPE NUMBER ENAME TOTAL ELAPSED AVG ELAPSED

1 12 SOLID279 0.0002 0.000020383

2 40 SOLID279 0.0013 0.000032352

3 20 SOLID279 0.0006 0.000028104

4 8 SOLID279 0.0003 0.000043264

5 4 CONTA174 0.0000 0.000005502

7 4 CONTA174 0.0000 0.000005770

9 4 CONTA174 0.0000 0.000006078

11 30 SURF252 0.0001 0.000004302

*** LOAD STEP 1 SUBSTEP 1 COMPLETED. CUM ITER = 3

*** TIME = 1.00000 TIME INC = 1.00000

*** MAPDL BINARY FILE STATISTICS

BUFFER SIZE USED= 16384

0.062 MB WRITTEN ON ELEMENT SAVED DATA FILE: file0.esav

0.125 MB WRITTEN ON ASSEMBLED MATRIX FILE: file0.full

0.312 MB WRITTEN ON RESULTS FILE: file0.rth

*************** Write FE CONNECTORS *********

WRITE OUT CONSTRAINT EQUATIONS TO FILE= file.ce

****************************************************

*************** FINISHED SOLVE FOR LS 1 *************

****************************************************

******************* SOLVE FOR LS 2 OF 2 ****************

PRINTOUT RESUMED BY /GOP

USE AUTOMATIC TIME STEPPING THIS LOAD STEP

USE 1 SUBSTEPS INITIALLY THIS LOAD STEP FOR ALL DEGREES OF FREEDOM

FOR AUTOMATIC TIME STEPPING:

USE 10 SUBSTEPS AS A MAXIMUM

USE 1 SUBSTEPS AS A MINIMUM

TIME= 2.0000

ERASE THE CURRENT DATABASE OUTPUT CONTROL TABLE.

WRITE ALL ITEMS TO THE DATABASE WITH A FREQUENCY OF NONE

FOR ALL APPLICABLE ENTITIES

WRITE NSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE RSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EANG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE VENG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE FFLU ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE CONT ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE NLOA ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE MISC ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

CONVERGENCE ON HEAT BASED ON THE NORM OF THE N-R LOAD

WITH A TOLERANCE OF 0.1000E-03 AND A MINIMUM REFERENCE VALUE OF 0.1000E-05

USING THE L2 NORM (CHECK THE SRSS VALUE)

UNDER RELAXATION FOR RADIATION FLUX= 0.10000

TOLERENCE FOR RADIOSITY FLUX= 0.00010

USING JACOBI ITERATIVE SOLVER FOR RADIOSITY SOLUTION

FOR 3D ENCLOSURES.

USING GSEIDEL ITERATIVE SOLVER FOR RADIOSITY SOLUTION

FOR 2D ENCLOSURES.

MAXIMUM NUMBER OF ITERATIONS= 1000

TOLERENCE FOR ITERATIVE SOLVER= 0.10000

RELAXATION FOR ITERATIVE SOLVER= 0.10000

HEMICUBE RESOLUTION= 10

MIN NORMALIZED DIST BEFORE AUTO SUBDIVIDE= 1.000000000E-06

***** MAPDL SOLVE COMMAND *****

*** NOTE *** ELAPSED TIME = 0.793 TIME= 22:14:39

This nonlinear analysis defaults to using the full Newton-Raphson

solution procedure. This can be modified using the NROPT command.

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2026 R1 26.1 ***

Ansys Mechanical Enterprise

00000000 VERSION=LINUX x64 22:14:39 JAN 27, 2026 Elapsed Time= 0.797

--Steady-State Thermal

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 2

TIME AT END OF THE LOAD STEP. . . . . . . . . . 2.0000

AUTOMATIC TIME STEPPING . . . . . . . . . . . . ON

INITIAL NUMBER OF SUBSTEPS . . . . . . . . . 1

MAXIMUM NUMBER OF SUBSTEPS . . . . . . . . . 10

MINIMUM NUMBER OF SUBSTEPS . . . . . . . . . 1

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS. . . . 15

STEP CHANGE BOUNDARY CONDITIONS . . . . . . . . NO

TERMINATE ANALYSIS IF NOT CONVERGED . . . . . .YES (EXIT)

CONVERGENCE CONTROLS

LABEL REFERENCE TOLERANCE NORM MINREF

HEAT 0.000 0.1000E-03 2 0.1000E-05

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS

ITEM FREQUENCY COMPONENT

ALL NONE

NSOL ALL

RSOL ALL

EANG ALL

VENG ALL

FFLU ALL

CONT ALL

NLOA ALL

MISC ALL

SOLUTION MONITORING INFO IS WRITTEN TO FILE= file.mntr

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS HAS BEEN MODIFIED

TO BE, NEQIT = 1000, BY SOLUTION CONTROL LOGIC.

RADIOSITY SOLVER CALCULATION

ENCLOSURE NUMBER= 1

RADIOSITY SOLVER CONVERGED AFTER 1 ITERATIONS

ELAPSED TIME OF RADIOSITY SOLVER FOR ENCLOSURE= 0.390298E-04

RAD FLUX CONVERGENCE VALUE= 0.944177E-04 CRITERION= 0.100000E-03

RADIOSITY FLUX CONVERGED AFTER ITERATION= 1 SUBSTEP= 1

HT FLOW CONVERGENCE VALUE= 9556. CRITERION= 0.9647

EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 30.00

HT FLOW CONVERGENCE VALUE= 0.2317E-08 CRITERION= 0.1477 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 1

RADIOSITY SOLVER CALCULATION

ENCLOSURE NUMBER= 1

RADIOSITY SOLVER CONVERGED AFTER 50 ITERATIONS

ELAPSED TIME OF RADIOSITY SOLVER FOR ENCLOSURE= 0.476730E-03

RAD FLUX CONVERGENCE VALUE= 0.166460 CRITERION= 0.100000E-03

HT FLOW CONVERGENCE VALUE= 42.99 CRITERION= 0.1551

EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.8913

HT FLOW CONVERGENCE VALUE= 0.1780E-08 CRITERION= 0.1561 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 2

RADIOSITY SOLVER CALCULATION

ENCLOSURE NUMBER= 1

RADIOSITY SOLVER CONVERGED AFTER 19 ITERATIONS

ELAPSED TIME OF RADIOSITY SOLVER FOR ENCLOSURE= 0.235660E-03

RAD FLUX CONVERGENCE VALUE= 0.477488E-02 CRITERION= 0.100000E-03

HT FLOW CONVERGENCE VALUE= 3.489 CRITERION= 0.1593

EQUIL ITER 3 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.7874E-01

HT FLOW CONVERGENCE VALUE= 0.1879E-08 CRITERION= 0.1594 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 3

RADIOSITY SOLVER CALCULATION

ENCLOSURE NUMBER= 1

RADIOSITY SOLVER CONVERGED AFTER 4 ITERATIONS

ELAPSED TIME OF RADIOSITY SOLVER FOR ENCLOSURE= 0.633400E-04

RAD FLUX CONVERGENCE VALUE= 0.513026E-03 CRITERION= 0.100000E-03

HT FLOW CONVERGENCE VALUE= 0.9038 CRITERION= 0.1606

EQUIL ITER 4 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.2237E-01

HT FLOW CONVERGENCE VALUE= 0.2546E-08 CRITERION= 0.1607 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 4

RADIOSITY SOLVER CALCULATION

ENCLOSURE NUMBER= 1

RADIOSITY SOLVER CONVERGED AFTER 1 ITERATIONS

ELAPSED TIME OF RADIOSITY SOLVER FOR ENCLOSURE= 0.383600E-04

RAD FLUX CONVERGENCE VALUE= 0.116168E-03 CRITERION= 0.100000E-03

HT FLOW CONVERGENCE VALUE= 0.3607 CRITERION= 0.1612

EQUIL ITER 5 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.8656E-02

HT FLOW CONVERGENCE VALUE= 0.1593E-08 CRITERION= 0.1612 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 5

RADIOSITY SOLVER CALCULATION

ENCLOSURE NUMBER= 1

RADIOSITY SOLVER CONVERGED AFTER 1 ITERATIONS

ELAPSED TIME OF RADIOSITY SOLVER FOR ENCLOSURE= 0.386000E-04

RAD FLUX CONVERGENCE VALUE= 0.110441E-03 CRITERION= 0.100000E-03

HT FLOW CONVERGENCE VALUE= 0.2014 CRITERION= 0.1612

EQUIL ITER 6 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.4221E-02

HT FLOW CONVERGENCE VALUE= 0.3392E-08 CRITERION= 0.1612 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 6

RADIOSITY SOLVER CALCULATION

ENCLOSURE NUMBER= 1

RADIOSITY SOLVER CONVERGED AFTER 1 ITERATIONS

ELAPSED TIME OF RADIOSITY SOLVER FOR ENCLOSURE= 0.566400E-04

RAD FLUX CONVERGENCE VALUE= 0.964750E-04 CRITERION= 0.100000E-03

RADIOSITY FLUX CONVERGED AFTER ITERATION= 7 SUBSTEP= 1

HT FLOW CONVERGENCE VALUE= 0.3695 CRITERION= 0.1609

EQUIL ITER 7 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.8624E-02

HT FLOW CONVERGENCE VALUE= 0.2478E-08 CRITERION= 0.1609 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 7

*** LOAD STEP 2 SUBSTEP 1 COMPLETED. CUM ITER = 10

*** TIME = 2.00000 TIME INC = 1.00000

****************************************************

*************** FINISHED SOLVE FOR LS 2 *************

FINISH SOLUTION PROCESSING

***** ROUTINE COMPLETED ***** ELAPSED TIME = 0.899

*GET _WALLASOL FROM ACTI ITEM=TIME WALL VALUE= 0.249732167E-03

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2026 R1 26.1 ***

Ansys Mechanical Enterprise

00000000 VERSION=LINUX x64 22:14:39 JAN 27, 2026 Elapsed Time= 0.900

--Steady-State Thermal

***** MAPDL RESULTS INTERPRETATION (POST1) *****

*** NOTE *** ELAPSED TIME = 0.900 TIME= 22:14:39

Reading results into the database (SET command) will update the current

displacement and force boundary conditions in the database with the

values from the results file for that load set. Note that any

subsequent solutions will use these values unless action is taken to

either SAVE the current values or not overwrite them (/EXIT,NOSAVE).

Set Encoding of XML File to:ISO-8859-1

Set Output of XML File to:

PARM, , , , , , , , , , , ,

, , , , , , ,

DATABASE WRITTEN ON FILE parm.xml

EXIT THE MAPDL POST1 DATABASE PROCESSOR

***** ROUTINE COMPLETED ***** ELAPSED TIME = 0.901

PRINTOUT RESUMED BY /GOP

*GET _WALLDONE FROM ACTI ITEM=TIME WALL VALUE= 0.250313580E-03

PARAMETER _PREPTIME = 0.8817410204E-02

PARAMETER _SOLVTIME = 0.2200980000

PARAMETER _POSTTIME = 0.2093089796E-02

PARAMETER _TOTALTIM = 0.2310085000

*GET _DLBRATIO FROM ACTI ITEM=SOLU DLBR VALUE= 1.13333333

*GET _COMBTIME FROM ACTI ITEM=SOLU COMB VALUE= 0.176241020E-02

*GET _SSMODE FROM ACTI ITEM=SOLU SSMM VALUE= 2.00000000

*GET _NDOFS FROM ACTI ITEM=SOLU NDOF VALUE= 642.000000

/FCLEAN COMMAND REMOVING ALL LOCAL FILES

--- Total number of nodes = 685

--- Total number of elements = 128

--- Element load balance ratio = 1.13333333

--- Time to combine distributed files = 1.762410204E-03

--- Sparse memory mode = 2

--- Number of DOF = 642

EXIT MAPDL WITHOUT SAVING DATABASE

NUMBER OF WARNING MESSAGES ENCOUNTERED= 1

NUMBER OF ERROR MESSAGES ENCOUNTERED= 0

+--------------------- M A P D L S T A T I S T I C S ------------------------+

Release: 2026 R1 Build: 26.1 Update: UP20260112 Platform: LINUX x64

Date Run: 01/27/2026 Time: 22:14 Process ID: 20576

Operating System: Ubuntu 22.04.5 LTS

Processor Model: AMD EPYC 7763 64-Core Processor

Compiler: Intel(R) Fortran Compiler Classic Version 2021.9 (Build: 20230302)

Intel(R) C/C++ Compiler Classic Version 2021.9 (Build: 20230302)

AOCL-BLAS 5.1.1 Build 20251007

Intel(R) oneAPI Math Kernel Library Version 2024.2-Product Build 20240605

Number of machines requested : 1

Total number of cores available : 16

Number of physical cores available : 8

Number of processes requested : 4

Number of threads per process requested : 1

Total number of cores requested : 4 (Distributed Memory Parallel)

MPI Type: OPENMPI

MPI Version: Open MPI v4.1.8

GPU Acceleration: Not Requested

Job Name: file0

Input File: dummy.dat

Core Machine Name Working Directory

-----------------------------------------------------

0 d42525df87ef /github/home/.mw/Application Data/Ansys/v261/AnsysMechC4C6/Project_Mech_Files/SteadyStateThermal

1 d42525df87ef /github/home/.mw/Application Data/Ansys/v261/AnsysMechC4C6/Project_Mech_Files/SteadyStateThermal

2 d42525df87ef /github/home/.mw/Application Data/Ansys/v261/AnsysMechC4C6/Project_Mech_Files/SteadyStateThermal

3 d42525df87ef /github/home/.mw/Application Data/Ansys/v261/AnsysMechC4C6/Project_Mech_Files/SteadyStateThermal

Latency time from master to core 1 = 1.836 microseconds

Latency time from master to core 2 = 1.841 microseconds

Latency time from master to core 3 = 1.852 microseconds

Communication speed from master to core 1 = 17295.91 MB/sec

Communication speed from master to core 2 = 16732.45 MB/sec

Communication speed from master to core 3 = 17873.34 MB/sec

Total CPU time for main thread : 0.7 seconds

Total CPU time summed for all threads : 1.6 seconds

Elapsed time spent obtaining a license : 0.4 seconds

Elapsed time spent pre-processing model (/PREP7) : 0.0 seconds

Elapsed time spent solution - preprocessing : 0.0 seconds

Elapsed time spent computing solution : 0.1 seconds

Elapsed time in element formation & assembly : 0.1 seconds

Elapsed time in equation solver : 0.1 seconds

Elapsed time in element result calculations : 0.0 seconds

Elapsed time spent solution - postprocessing : 0.0 seconds

Elapsed time spent post-processing model (/POST1) : 0.0 seconds

Equation solver used : Sparse (symmetric)

Sparse direct equation solver computational rate : 1.2 Gflops

Sparse direct equation solver effective I/O rate : 1.4 GB/sec

Sum of disk space used on all processes : 1.9 MB

Sum of memory used on all processes : 196.0 MB

Sum of memory allocated on all processes : 2880.0 MB

Physical memory available : 63 GB

Total amount of I/O written to disk : 0.0 GB

Total amount of I/O read from disk : 0.0 GB

+------------------ E N D M A P D L S T A T I S T I C S -------------------+

*-----------------------------------------------------------------------------*

| |

| RUN COMPLETED |

| |

|-----------------------------------------------------------------------------|

| |

| Ansys MAPDL 2026 R1 Build 26.1 UP20260112 LINUX x64 |

| |

|-----------------------------------------------------------------------------|

| |

| Database Requested(-db) 1024 MB Scratch Memory Requested 1024 MB |

| Max Database Used(Master) 1 MB Max Scratch Used(Master) 48 MB |

| Max Database Used(Workers) 1 MB Max Scratch Used(Workers) 48 MB |

| Sum Database Used(All) 4 MB Sum Scratch Used(All) 192 MB |

| |

|-----------------------------------------------------------------------------|

| |

| CP Time (sec) = 1.649 Time = 22:14:39 |

| Elapsed Time (sec) = 1.110 Date = 01/27/2026 |

| |

*-----------------------------------------------------------------------------*

Print the project tree#

app.print_tree()

├── Project

| ├── Model

| | ├── Geometry Imports (✓)

| | | ├── Geometry Import (✓)

| | ├── Geometry (✓)

| | | ├── Part4

| | | | ├── Part4

| | | ├── Part3

| | | | ├── Part3

| | | ├── Part2

| | | | ├── Part2

| | | ├── Part1

| | | | ├── Part1

| | ├── Construction Geometry (✓)

| | | ├── Path (✓)

| | | ├── Surface (✓)

| | ├── Materials (✓)

| | | ├── Structural Steel (✓)

| | ├── Coordinate Systems (✓)

| | | ├── Global Coordinate System (✓)

| | | ├── Coordinate System (✓)

| | | ├── Coordinate System 2 (✓)

| | ├── Remote Points (✓)

| | ├── Connections (✓)

| | | ├── Contacts (✓)

| | | | ├── Contact Region (✓)

| | | | ├── Contact Region 2 (✓)

| | | | ├── Contact Region 3 (✓)

| | ├── Mesh (✓)

| | ├── Named Selections

| | | ├── Face1 (✓)

| | | ├── Face2 (✓)

| | | ├── Face3 (✓)

| | | ├── Body1 (✓)

| | ├── Steady-State Thermal (✓)

| | | ├── Initial Temperature (✓)

| | | ├── Analysis Settings (✓)

| | | ├── Temperature (✓)

| | | ├── Temperature 2 (✓)

| | | ├── Radiation (✓)

| | | ├── Solution (✓)

| | | | ├── Solution Information (✓)

| | | | ├── Temperature (✓)

| | | | ├── Temperature 2 (✓)

| | | | ├── Temperature 3 (✓)

| | | | ├── Temperature 4 (✓)

| | | | ├── Total Heat Flux (✓)

| | | | ├── Directional Heat Flux (✓)

| | | | ├── Thermal Error (✓)

| | | | ├── Temperature Probe (✓)

| | | | ├── Heat Flux Probe (✓)

| | | | ├── Reaction Probe (✓)

| | | | ├── Radiation Probe (✓)

Clean up the app and downloaded files#

# Save the project file

mechdat_path = output_path / "steady_state_thermal.mechdat"

app.save(str(mechdat_path))

# Close the app

app.close()

# Delete the example files

delete_downloads()

True

Total running time of the script: (0 minutes 18.003 seconds)